Oil Circuit Breaker (OCB) – Types, Construction, Working and Applications

OCB – Oil Circuit Breaker – Construction and Working Principle

Circuit breakers are protection devices that protect circuits and equipment during fault conditions. They use different kinds of dielectric mediums to break the circuit safely. For instance, insulating oil is used as a dielectric medium inside the oil circuit breakers due to its excellent arc quenching properties. It is one of the oldest high voltage circuit breakers still being used.

What is Oil Circuit Breaker (OCB)?

An Oil circuit breaker aka OCB is a type of circuit breaker that uses insulating oil as a dielectric medium to quench the arc and break the circuit safely. The oil used is insulating oil used usually transformer oil that has better dielectric strength than air. The heat produced by the arc vaporizes the oil, producing a hydrogen gas bubble surrounding the arc. The pressure of the oil compresses the gas bubble increasing its dielectric strength which extinguishes the arc during the zero-crossing.

Related Posts:

- SF6 Circuit Breaker – Types, Construction, Working and Applications

- Air Circuit Breaker (ACB) – Construction, Operation, Types and Uses

Working Principle of OCB

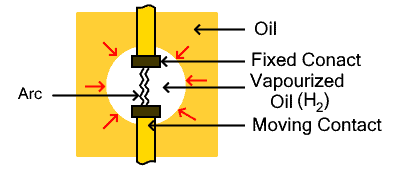

When a fault condition occurs, the current-carrying contacts are separated inside the insulating oil. As the contacts separate, the high voltage difference between the contacts ionizes the medium surrounding it and an arc is struck. The immense heat generated by arc vaporizes the oil surrounding the contacts. The oil is decomposed into mostly hydrogen gas including a small amount of methane, ethylene, and acetylene. The decomposed gases form a gas bubble surrounding the contacts.

The hydrogen gas breaks into atomic form releasing immense heat that increases the temperature of the arc. Consequently, the oil vaporization increases. The volume of the gas produced is 1000 times larger than the oil decomposed. Due to high temperatures, the volume of the gas bubble rapidly increases. The surrounding oil inside an enclosed container puts a lot of pressure on the gas bubble. Due to compression, the ionized medium surrounding the contacts starts to de-ionize. As the pressure keeps increasing due to the heat of arc, the medium rapidly de-ionizes that increases the dielectric strength of the medium. The arc is quenched at the next current zero-crossing.

Besides that, the cooling effect of the oil and the gas bubbles also helps in arc quenching

Types of Oil Circuit Breaker

The oil circuit breaker can be classified into the following two main types

- Bulk Oil Circuit Breaker (BOCB)

- Minimum Oil Circuit Breaker (MOCB)

Bulk Oil Circuit Breaker- Such type of oil circuit breaker uses a large quantity of insulating oil. The oil is used for arc quenching as well as insulating the live parts from the earth parts of the breaker.

Minimum Oil Circuit Breaker- Such type of oil circuit breaker uses a small amount of oil only for arc quenching.

Bulk Oil Circuit Breaker (BOCB)

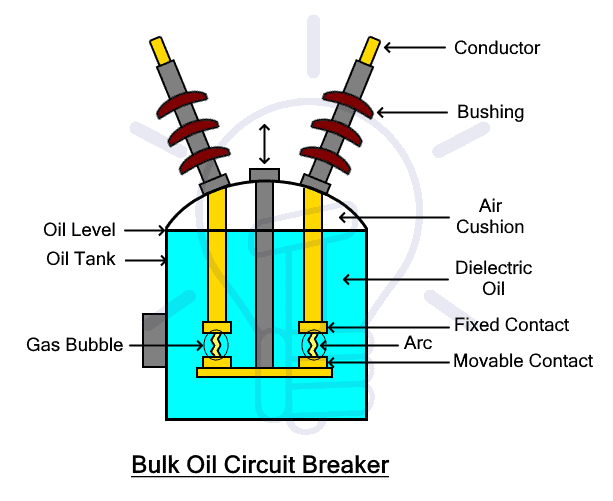

Bulk oil circuit breaker uses a large quantity of oil. The oil used serves two purposes. It extinguishes the arc when the contacts separate and it also insulates the live current-carrying parts from the earthed parts of the circuit breaker.

BOCB can be classified into the following two types

- Plain Break Oil Circuit Breaker

- Arc Control Oil Circuit Breaker

Plain Break Oil Circuit Breaker- Such BOCB does not have any control over the arc except for increasing the arc length by separating the contacts. they are fairly simple and easier to design

Arc Control Oil Circuit Breaker- Such BOCB has a special system for arc control that efficiently quenches the arc.

Plain Break Oil Circuit Breaker

Such BOCB is the simplest and oldest form of oil circuit breakers. There is no arc control system. Its operation is very simple. The current-carrying contacts are separated inside oil where the length of the arc increases with separation between the contacts. The arc quenches at the first zero current crossing.

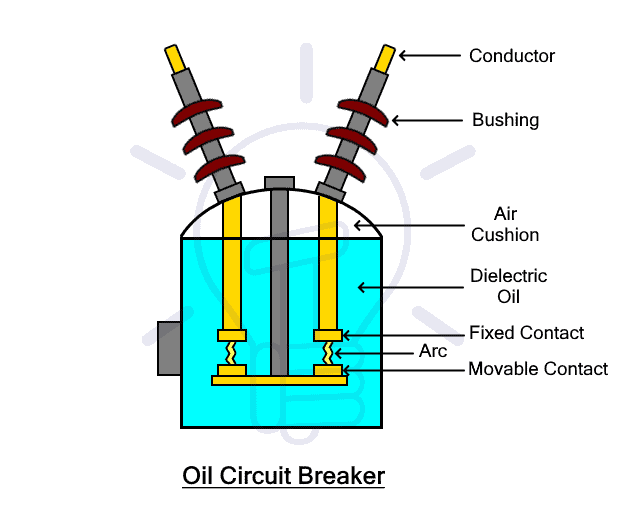

Construction- Its construction is quite simple. It has a tank made from strong metal that contains the insulating transformer oil. The current-carrying contacts are submerged in the oil. The body of the tank is earthed. The oil acts as both an arc quenching medium as well as an insulator between the live contacts and earthed body. The tank is not completely filled with oil but some space is left for air that acts as a cushion for the displaced oil during oil vaporization. It absorbs the pressure released from the gas. The tank also includes vents for the gas outlet.

Under fault conditions, the moving contact moves downward to separate from fixed contacts. During the contact separation, the separation gap increases. due to the high voltage difference, the oil starts to ionize and an arc is struck between the contacts.

The heat of the arc vaporizes the oil between the contacts and converts it into mostly hydrogen gas. The gas forms a bubble surrounding the contacts which increase in volume very rapidly. The gas bubble displaces the oil which is absorbed by the air cushion. The surrounding oil compresses the gas bubble that de-ionizes the medium. The dielectric strength of the medium between the contacts increases. The contact separation also increases the arc length increasing the medium dielectric strength. The arc is quenched at the next current zero-crossing.

The main disadvantage of a plain break oil circuit breaker is that it does not have arc control and it relies on contact separation that increases the arc length. It is inconsistent and takes longer arcing times. The arc is quenched when the contacts are fully separated. Due to these limitations, a plain break oil circuit breaker is used for low voltage 11kV systems.

Arc Control Oil Circuit Breaker

Such BOCB includes a special system designed to control the arc to efficiently quench it. These designs enable the CB to extinguish the arc even if the contact gap is small. Unlike plain-break OCB, these CBs can be used in high voltage circuits.

The arc control Oil circuit breaker can be classified into the following two types.

- Self-Blast Oil Circuit Breaker

- Forced Blast Oil Circuit Breaker

Self-Blast Oil Circuit Breaker- In such OCB, the arc is controlled by internal means such as the energy of the arc is used for its own extinction.

Forced Blast Oil Circuit Breaker- In such OCB, the arc control is provided by external means.

Self-Blast Oil Circuit Breaker

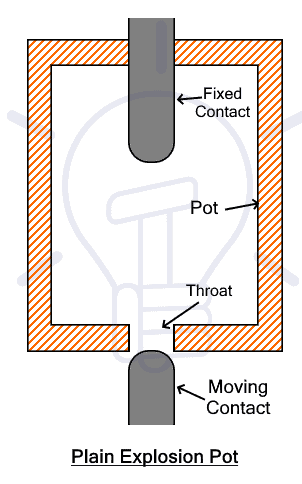

In self-blast OCB, the contacts are surrounded by a chamber called pressure chamber or explosion pot. It is made from insulating material. The gas produced by the arc is accumulated inside the pressure chamber. It has a small volume thus having high pressure. The amount of pressure exerted is directly proportional to the arc current. It reduces the contact gap required for successful arc extinction, as well as reduces the arcing time.

Self-blast oil circuit breaker’s explosion pot can be designed in the following designs each providing its own benefits.

- Plain Explosion Pot

- Cross Jet Explosion Pot

- Self-Compensated Explosion Pot

Plain Explosion Pot

Such a type of explosion Pot is very simple. It is a cylindrical-shaped pot made from insulating material. It includes fixed and moving contact. The moving contact pass through a narrow hole called the throat.

Under fault conditions, the contact separate and arc is struck. The arc vaporizes the oil, producing gas with high pressure. The high pressure compresses the oil to deionize the medium and quench the arc at zero crossings. When the moving contact leaves the pot, cool oil and gas rush through the throat that also helps in quenching the arc.

Plain explosion pot cannot be used for very low or very high currents. as the pressure is directly proportional to the arc current, low current produces very low pressure which may not be enough to quench the arc in time thus increasing the arcing time. on the other hand, a very high arc current may produce very high pressure that can explode the pot. Therefore, such an explosion pot is used for medium current.

- Related Post: Circuit Breaker, Fuse and Protection Symbols

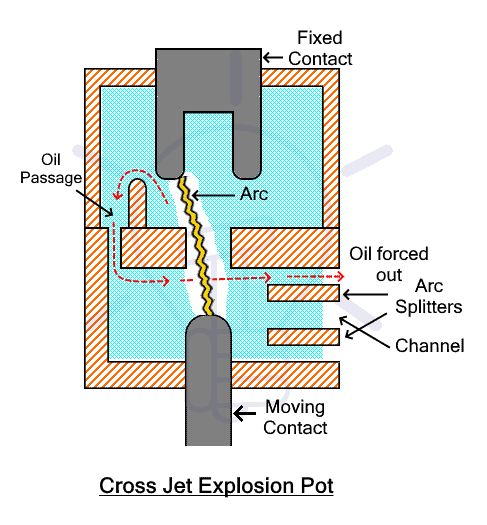

Cross Jet Explosion Pot

Such type of explosion pot is a modified form of plain explosion pot. It includes channels on one side of the pot that also acts as arc splitters. The arc splitter splits the arc increasing its length that helps in quenching the arc. The side channels are used for allowing a path for cool oil to enter the chamber and cool off the arc.

During fault conditions, the contacts start to separate and an arc is struck at the top portion of the pot. The arc heat vaporizes the oil generating pressure that exerts a force on the oil through the passage. When the moving contact moves further down, it unblocks the channel arc splitters. It splits the arc increasing its length that helps in quenching the arc at zero crossing.

Cross jet explosion pot is used for a very high current with a very low arcing time. it is not suitable for low current because low current cannot generate enough pressure to quickly quench the arc.

Self-Compensated Explosion Pot

This type of explosion pot is made from a combination of plain and cross jet explosion pot. It has two chambers; the upper chamber is a cross-jet explosion pot while the lower chamber is a plain explosion pot as shown in the figure.

If the fault current is very high, the pressure generated will be high. As soon as the moving contacts unblock the arc splitter ducts, the oil rushes out and the arc is split and extinguish.

If the fault current is low, the pressure builds slowly. As the moving contacts take time to pass through the throat, the pressure build-up inside the chamber. There is a little leakage through the arc splitter ducts. The arc successfully extinguishes in the lower chamber when the moving contact completely passes through the throat.

Related Post: Difference Between MCB, MCCB, ELCB and RCB, RCD or RCCB Circuit Breakers

Forced Blast Oil Circuit Breaker

In a force blast oil circuit breaker, the necessary pressure generated for arc quenching does not depend on the internal means (arc current) but it is generated by external means. A mechanical piston that is coupled with the movement of the moving contact presses against the oil to increase its pressure. it safely quenches the arc irrespective of the arc current.

Therefore, force-blast OCB has no limitation like self-blast OCB because it does not depend on the arc current. It can safely extinguish low, medium and high arc currents.

Based on the breaking of the current-carrying contacts, BOCB is divided into two types

- Single Break Bulk Oil Circuit Breaker

- Double Break Bulk Oil Circuit Breaker

Single Break Bulk Oil Circuit Breaker

As the name suggests, such BOCB has only one break between the current-carrying contacts. There is only one fixed contact and one moving contact as shown in the figure. The arc control OCB has a single break OCB design. Upon fault condition, such breakers generate a single arc. Since arc control OCB depends on the pressure generated by the heat of the arc, a single arc generates much more heat and high pressure to deionize the medium.

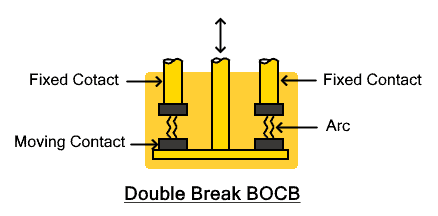

Double Break Bulk Oil Circuit Breaker

Double break OCB has two breaks between its current-carrying contacts when it opens. There are two fixed contacts and one moving contact. When it separates, two arcs at both ends of the contacts are generated. It lengthens the arc but decreases the heat produced by the arc at one spot.

Plain-Break OCB has a double-break design because it quenches the arc by lengthening the arc and double-break design offers that by breaking the arc into two.

Advantages

- The oil used for arc quenching has very high dielectric strength

- The oil insulates the live contacts from the earthed parts

- The oil produces hydrogen gas with the heat from the arc which is beneficial for arc quenching.

- The pressure of oil compresses the gas to deionize the medium.

- The gas also helps in cooling the medium.

Disadvantages

- The oil is inflammable and causes a fire hazard.

- The contacts can get damaged with the arc.

- The carbonization of the oil from the contacts reduces its dielectric strength.

- The contacts and the oil must be checked and maintained regularly.

- The use of a huge amount of oil increases its cost

- Their large oil-filled tanks are heavy and take large space.

Related Post: Difference between Fuse and Circuit Breaker

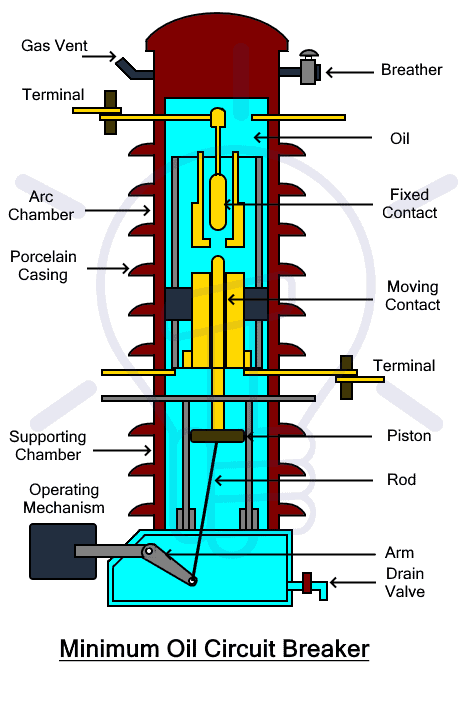

Minimum Oil Circuit Breaker (MOCB)

The minimum oil circuit breaker (MOCB) also known as the low oil circuit breaker is a major type of oil circuit breaker that uses oil only for extinguishing the arc. On the contrary, BOCB uses it for insulating the live part from earth parts as well. The main advantage of using less oil is to reduce fire hazards. It does not act as insulation between the live and earthed parts.

The MOCB has two chambers; the arc chamber and the supporting chamber. The arc chamber includes fixed and moving contact filled with oil. This chamber is used for extinguishing the arc. It is made from porcelain with bakelised paper encasing. It also includes vents for gas release at the top.

The supporting chamber provides support to the arc chamber. It is made of porcelain filled with oil for insulation. It insulates the arc chamber that is mounted on top of it. It includes an arm operated by a mechanism to move the moving contact upward and downward using a rod. The moving contact is also attached to a piston that develops the pressure necessary for arc quenching. Therefore, MOCB is a type of Forced Blast oil circuit breaker where the pressure is developed by external means independent of the arc current.

The working of MOCB is simple. Under fault conditions, the arm pulls the moving contact downward separating the contact. An arc is generated between the contacts. the arc energy vaporizes the oil generating necessary pressure. The pressure is confined to the arc chamber as it is blocked by the moving contact. As soon as the moving contacts unblock the hole, cool oil rushes in and the gases flow out through the vent.

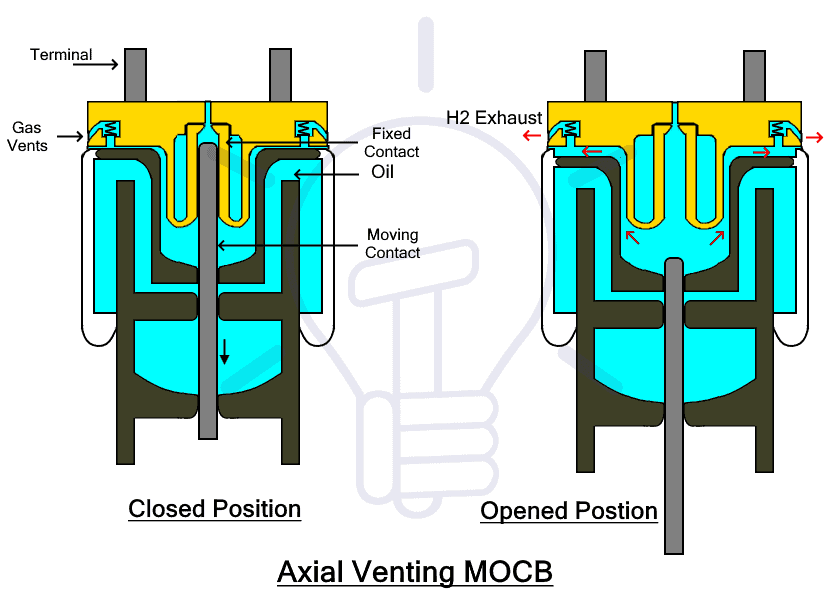

The gas vents of the arcing chamber can be designed in one of the two following ways, therefore, MOCB is divided into two types.

Axial Venting MOCB

The following figure shows axial venting MOCB where the arc chamber vents are designed is such a way that when the contacts separate. The cool oil enters through the path unblocked by the moving contact. The arc is swept in an axial direction through the upper vent.

The axial venting generates very high pressure thus having very high de-ionization capabilities and consequently high dielectric strength of the oil. It is used for low arc current at high voltages.

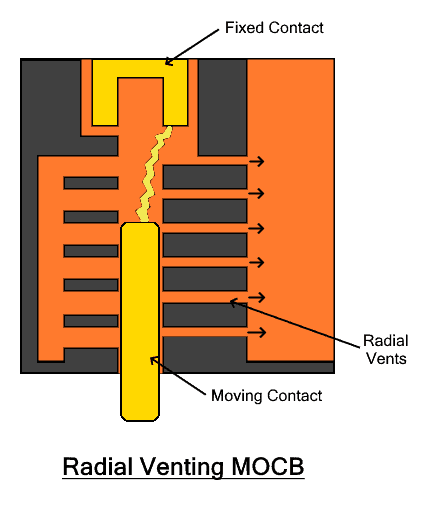

Radial Venting MOCB

The radial venting MOCB has multiple vents designed radially along with the arc chamber as suggested by its name. When the arc is stretched between the contacts, the arc is swept radially through the vents. Such design developed low pressure therefore, it is used for high arc current.

A combination of both axial and radial venting arc chambers in MOCB is used for efficiently quenching both low and high arc current.

Oil Impulse Circuit Breaker

The Oil impulse circuit breaker is another type of MOCB that develops pressure by external means. A piston compresses the oil that is released through a jet fixated between the contacts to quench the arc. It uses lesser oil than MOCB. Since the pressure is independent of the arc current, it can be used for low as well as high arc current.

Advantages

- It requires a very little amount of oil.

- Less amount of oil means the risk of fire hazards is low.

- It has low weight.

- It has small size and takes up small space

- It is cheaper than BOCB.

- It has easier maintenance and oil can be easily replaced.

- Best for installation in places where it is not frequently used.

Disadvantages

- Lesser oil is more affected by the amount of carbonization from the contacts.

- The oil quickly losses its dielectric strength.

- It requires more frequent maintenance.

Maintenance of Oil Circuit Breaker

During a fault condition, the arc can damage the contacts and the oil can get carbonized which decreases the dielectric strength of the oil. Consequently, its breaking capacity is reduced and the breaker may fail. Therefore, the contacts, as well as the oil, should be monitored and replaced to maintain its dielectric strength.

Advantages & Disadvantages of of Oil Circuit Breakers

Advantages

- The oil used is a better arc quenching medium than air.

- The oil used has very high dielectric strength

- The dielectric strength of the oil increase with the increase in pressure.

- The arc energy is utilized to vaporize the oil to increase its pressure.

- The oil is also used as insulation between live and earthed parts.

- The gas vapors also help in cooling the medium.

- Oil circuit breakers are cheaper than other high voltage oil-less circuit breaker

Disadvantages

- The oil is inflammable and can cause fire hazards.

- The oil can get carbonized that reduces its dielectric strength.

- It requires maintenance and replacement of contacts and oil with fresh oil.

Applications of Oil Circuit Breaker

The oil circuit breakers are used in high voltage applications such as in power grids, substations, powerlines and transmission and distribution systems for up to 220 kV.

Related Posts:

- How to Find the Proper Size of Circuit Breaker? Breaker Calculator and Examples

- HVDC Circuit Breaker – Types, Working and Applications

- Can We Use AC Circuit Breaker for DC Circuit and Vice Versa?

- Electronic Circuit Breaker – Schematic and Working

- Smart WiFi Circuit Breaker – Construction, Installation and Working

- Why Circuit Breaker Capacity Was Rated in MVA and Now in kA and kV?

- How to Wire 120V and 240V Main Panel? Breaker Box Installation – US – NEC

- How to Wire Single-Phase, 230V Consumer Unit (Breaker Box) with RCD? IEC, UK and EU