Hydropower Plant – Types, Components, Turbines and Working

How a Hydropower Plant Works? Types of Turbines and Hydroelectric Power Plants

What is Hydropower Plant?

The hydropower plant or hydroelectric power plant is used to convert the kinetic energy of water into electrical energy. The kinetic energy developed in the water flow due to the gravity of falling water from higher to lower head.

The kinetic energy is used to rotate the turbine and the turbine is connected with an alternator to generate electrical energy. A hydroelectric power plant is a non-convention power plant and widely used to generate electricity from a renewable source of energy.

To achieve kinetic energy from water, the reservoir or dam is constructed at a high head from the ground level. The initial cost of a hydroelectric power plant is very high. But the running cost is very low. In the world, 16% of total power is generated from the hydroelectric power plant.

Layout and Components of Hydropower Plant

Generally, the hydroelectric power plant is constructed in a hilly area. The typical layout of a hydroelectric power plant is as shown in the figure below.

The major components of the hydroelectric power plant are listed below.

- Forebay

- Intake structure

- Penstock

- Surge tank

- Turbines

- Powerhouse

- Draft tube

- Tailrace

Related Post: Solar Power Plant – Types, Components, Layout and Operation

Let’s explain each component in detail.

Forebay

The forebay is used to store water temporarily before passes to the intake structure. The forebay is an optional component of a hydroelectric power plant.

The reservoir is used to store water across the river. In some hydroelectric power plants, the reservoir behaves as a forebay. And the water from the reservoir leads to the turbine.

The amount of water stored in the forebay is decided based on the demand of required water and load in that area.

Intake Structure

The intake structure is a chain between the penstock and forebay. It collects water from the forebay and passes to the penstock.

It plays an important role in power plants. The water comes in reservoir or forebay from the river. Therefore, the water contains much trash like trees and debris. The intake structure contains trash racks and placed trash racks at the entrance of the penstock.

The trash racks are made of steel rods. It prevents severe damage to the turbine blades and nozzle. In trash racks, steel rods are placed with a gap of 10 to 30 cm apart.

Trash racks are heated in cols season to avoid ice rocks collision with turbine blade. Due to heat in trash racks, the ice rocks melted at the entrance of the penstock. The trash racks must be clean after a regular time period. And racks and trolly arrangements are used to clean the trash racks.

Penstock

Penstocks are used to increase the velocity of the water. It is large pipes laid on the slope. It carries water from the reservoir or intake structure to the turbine.

The penstocks are open and close with the gate. So, at the time of opening and closing of gates, the pressure of water is very high. Therefore, the penstocks are designed to sustain the hammer of water.

Short length penstock has heavy wall and long length penstock has surge tank is used to overcome the pressure of water. The penstock is made of steel and reinforced concrete.

If the length of penstock is small, separate penstock is used for the turbine. If the length of penstock is large, a single penstock is used and at the end, it divides into branches.

Surge tank

A surge tank is a cylindrical tank or chamber placed near the powerhouse and it is connected with the penstock. The surge tank is also known as the surge chamber. It is used to control the pressure of water in the penstock.

The water level of the surge tank increases when the powerhouse rejects the water due to low power demand. So, the surge tank controls the pressure in the penstock.

When the power demand is high, a surge tank is used to accelerate the water flow. And in this condition, the water level of the surge tank is reduced. During steady load conditions, the water level becomes constant.

Turbine

The turbine is used to convert the kinetic energy of water into mechanical energy. When the high-pressure water coming from the penstock strikes the turbine blade, the turbine starts rotating.

The shaft is placed at the center of the turbine. And a generator is also connected with the same shaft and it further converts the mechanical energy into electrical energy.

There are mail two types of the turbine;

- Impulse turbine

- Reaction turbine

The impulse turbine is also known as a velocity turbine and the reaction turbine is also known as a pressure turbine.

Powerhouse

The powerhouse is used to provide support and housing to the hydraulic and electrical equipment. It is divided into two parts; substructure and superstructure.

The substructure can be an integral part of the hydraulic system or it can be placed away from the hydraulic system. It is used to provide support to the equipment and provide necessary ways to the water.

The superstructure contains the main unit and electrical accessories. The generators are placed on the ground floor with the turbine. Generally, for better visibility, the control room is placed on the first or second floor.

Draft tube

A draft tube connects the turbine outlet (turbine discharge) to the tailrace. To decrease the velocity of water, the width of the draft tube is gradually increased. The gates are provided at the end of a draft tube which is closed at the time of maintenance. In the case of the reaction turbine, the draft tube is a necessary component.

Tailrace

The tailrace is a flow of water from the draft tube or turbine outlet. The powerhouse must be located near to the stream. If the powerhouse is placed far from the stream, it is compulsory to build a way or channel to flow the water into a stream.

It will decrease the efficiency, cavitation, damage the turbine by silting caused unnecessary flow of water. Therefore, while designing a hydroelectric power plant, place the powerhouse near the stream.

- Related Post: What is Nuclear Power and How Nuclear Power Plant Works?

Working of Hydropower Plant

The hydroelectric power plant utilizes the energy stored in water to rotate a hydraulic turbine. The turbine is used to runs an electric generator to convert mechanical energy into electrical energy.

The rainwater saves by constructing dams across the river. The stored water on dams has potential energy which is used to generate electric power.

The electric power generated by hydroelectric power plants depends on the quantity of water available and the head of water.

A dam was constructed in a hilly area. So, the head of water available naturally. From the dam, waterfalls towards the blade of the turbine and turbine rotate with the force of water. Turbine and electrical generator connected on the same shaft.

Therefore, the generator generates electric power. The power generated from the powerhouse can be controlled by controlling the flow of water.

The advantage of this power plant is that it does not require any fuel. Therefore, the running cost of this plant is very less. It only requires the water head which is available naturally.

The formula for power generation in a hydroelectric power plant is given by;

Where,

- ρ = density of water = 9.81 kg/m3

- Q = discharge of water (m3/s)

- H = available head (m)

- n = system efficiency

Related Post: Why Power Plant Rated in MW and Not in kVA?

Types of Hydropower Plant

The hydroelectric power plants are classified into different types as follows.

Based on the availability of water head

- Low head plant

- Medium head plant

- High head plant

Based on the nature of the load

- Base load plant

- Peak load plant

Based on the quantity of water available

- Run-off river plants without pondage

- Run-off river plant with pondage

- Storage type plant

- Pumped storage peak load plant

- Mini and micro hydel plant

Based on the Availability of Water Head

According to the available water head, the power plants classifies into three types,

Low head plants

In this type of hydroelectric power plant, the available water head is less than 30m. In this type of plant, by constructing a dam, the water is stored. And the power plant is constructed at the base of the dam.

If the excess water is available in the dam, it will flow over the dam itself. In this type of plant, Francis, propellor, or Kaplan type turbines are used in most of the cases.

Medium head plant

The hydroelectric power plant which has an available water head of 30m to 100m is considered a medium head plant. In most cases, the Francis turbine is used in this type of power plant.

High head plant

The hydroelectric plant having an available water head is more than 100m consider a high head plant. In this type of plant, a bulk amount of water is available in the dam from the rain or melting of snow.

These plants are constructed in hilly areas to achieve high water head. In most cases, these plants are constructed on big rives in which the water is available throughout the year.

The high head plant uses Francis turbine up to the head of 300m and Pelton turbine uses if the available water head is more than 300m.

Based on the Nature of the Load

Two types of load can be connected with the power plant. The plant running continuously throughout the day is said to be a base load plant. And the plant which is used to meet the peak demand is known as peak load plants.

According to the type of load connected with the plant, the hydroelectric plants are classified into two types;

Base load plant

These plants are used to take a load on the base portion of the load curve of the power system network. The base load plants are large capacity plants as it is built to meet the demand of the base load.

The load factor of these plants is very high. In most cases, these plants are runoff river or storage type plants

Peak load plant

The hydroelectric power plant that was built only to meet the peak portion of the load curve is known as the peak load hydropower plant.

The capacity of this plant is less than base load plants and these plants are turned ON only while the peak demand of load and after this plant turned OFF. Therefore, these plants are used to run for a short duration of time.

In most cases, these plants are runoff river plants with pondage or storage type of hydel plant.

Based on the Quantity of Water Available

According to the quantity of water available to generate electric power, the hydroelectric power plants are classified into five types;

Run-off river plants without pondage

This type of hydropower plant does not store water. It uses the water directly from the river. The power output of these plants is not constant. Because there is no control over the availability of water. Hence, the power output fluctuates and the utility of this plant is very less compared to other plants.

Run-off river plants with pondage

In this type of plant, a pond is constructed behind the dam and near the plant. This pond increases the utility of the power plant.

To meet fluctuating loads, the capacity of the pond decides based on the 24 hours fluctuation in load demand. This plant can be used as a base load as well as a peak load plant.

Storage type plant

This type of plant uses a reservoir to store water. In some areas where the water is available in rainy seasons only. In this area, the storage type of plants is used to store water in bulk amounts and use in dry seasons.

The storage type of plant can be used as base load and peak load plant. The capacity of the plant decides by the water storage capacity of the reservoir.

Pumped storage peak load plant

This type of plant is used to meet the peak load demand. It has a reservoir to store the water. When the load demand is high, it used the water of the reservoir. And when the load demand is reduced, this plant is designed with a pump that is used to supply water from tailrace to head race.

The pumped storage plants are used to run along with the steam (thermal) power plant to improve the overall efficiency of a combined power plant. The pump of this plant is energized from the secondary power plant like run-off river plant or nuclear plant.

In this plant, the required water is very less compared to other hydropower plants.

Mini and micro hydel plant

Mini and micro hydropower plants are used to meet the power crises. Mini power plants work in the range of 5 to 20 m head and micro power plants work in the range of fewer than 5 m available water head.

This plant is a small capacity plant. and the time required and cost to build this plant are less compared to other hydroelectric plants. The mini-Hydropower Plant uses a special type of turbine known as bulb type turbine.

Site Selection of Hydropower Plant

The location of a hydroelectric power plant is the most important factor. Because to construct a hydropower plant, the capital cost to very high. Here, we discuss which factor must be considered while selecting a site for the hydroelectric power plant.

- Availability of water

- Storage capacity of water

- Water head

- Transportation facility

- Cost of land

- Water pollution

- Geological data

Availability of water

Water is the main requirement of a hydropower plant. Without water, this plant cannot operate. So, the plant must be constructed on land where the water is available throughout the year. In most cases, the hydropower plant is constructed over a river or canal to meet the high water demand. And check the previous years’ data of rainfall to confirm the availability of water.

Storage capacity of water

The natural main source of water is rainfall or melting of the ice mountain. In some countries, the rainfall is seasonal. So, to use plants throughout the year, we need to store a bulk amount of water. For that, a dam or pondage is constructed near the powerhouse. The capacity of water storage will decide the capacity of power generation and how much time it can operate without rainfall.

Water head

The hydropower plant uses the kinetic energy of water. If we have a high water head naturally, we can use the kinetic energy to rotate the turbine. In most cases, the dam is constructed in hilly areas where the water head is available naturally. So, it is necessary to select a site with a high head available naturally.

Transportation Facility

The hydropower plant requires heavy machinery to operate the plant as well as while constructing a dam, powerhouse, etc. Therefore, the selected site has an adequate transportation facility to transport machinery. Also, at the time of construction, it requires huge manpower. So, the place selected for the power plant has a good transportation facility. The power plant site must be accessible with rail or road transport.

Cost of land

The initial cost of this plant is very high. So, the land that is used to build dams and powerhouses must available at a reasonable price.

Water pollution

Water is the main fuel of the power plant. If the polluted water is supplied to the turbine blade, it may damage the turbine blade. And that will reduce the life of the turbine. Therefore, the supplied water must be free from pollution.

Geological data

The place chosen for a plant is capable to withstand the trust of water and other stress. There is no chance of land sliding. Otherwise, there are chances to fall dam and it creates flood situation in nearby areas. Before constructing a dam, we need to check the previous year’s data of earthquakes, thunderstorms, etc.

Related Posts:

- What is HVDC? High Voltage Direct Current Power Transmission

- Differences Between HVAC and HVDC Power Transmission

- Advantages of HVDC over HVAC Power Transmission

Different Types of Turbine used in Hydropower Plant

The turbines are used to convert the kinetic energy of water into mechanical energy. According to the available water head and flow or volume of water, the hydropower turbine is selected. The hydropower turbines are classified into two types;

- Impulse turbine

- Reaction turbine

Impulse Turbine:

As the name suggests, this turbine works on the principle of impulse. It uses the head of water and converts the pressure of water into kinetic energy with the help of nozzles.

In some plants, one or more nozzles are constructed near the runner. This will increase the velocity of the water. And this high-velocity water impinges on the turbine. The turbine has a number of buckets fixed on the outer periphery of the wheel.

The bucket is used to change the direction of jet flow if required. The momentum of water is used to convert kinetic energy into mechanical energy.

The pressure of water remains constant at atmospheric while passes through the runner. An example of impulse turbine is Pelton turbine, cross-flow turbine;

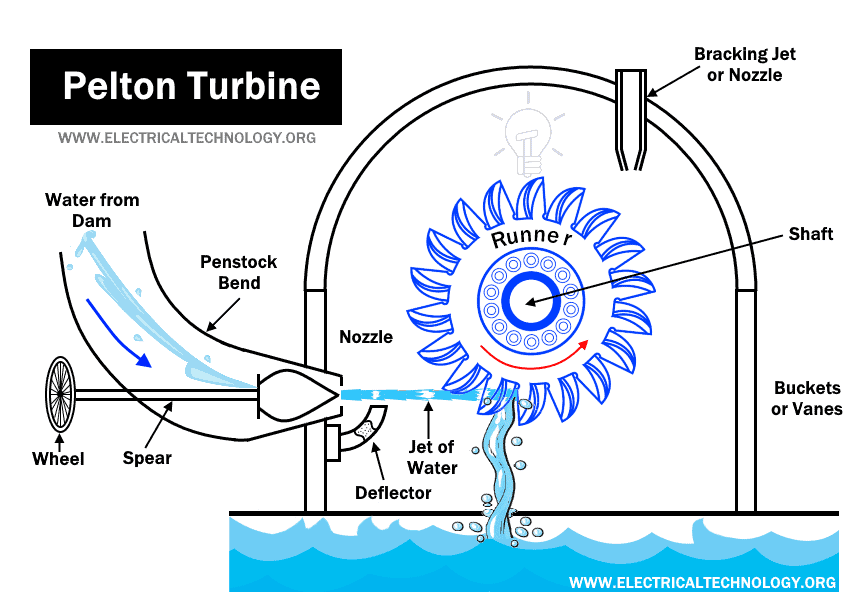

Pelton Turbine

In a Pelton turbine, the blades are spoon-shaped and the water is allowed to strike via a nozzle to the blade of a turbine. The blade of the Pelton turbine is also known as a bucket. Sometimes, the Pelton turbine is also known as the Pelton wheel.

In some cases, instead of one nozzle, a set of nozzles are used to split into a number of streams. These streams flow along the inner curve of the blade and pass in the opposite direction. This creates an impulse on the blade of the turbine and generates high torque by which the turbine starts rotating.

Generally, Pelton turbines are used in a hydroelectric power plant where the high head and low flow should consider. The plants which have available water head more than 985 feet and have a reservoir of water uses the Pelton wheel.

Cross-flow Turbine

The shape of the cross-flow turbine is similar to the drum and water wheel. This turbine is also known as the Ossberger turbine. The water strikes the rotor of the turbine. For the first time, pressured water transfers impulse force inside the drum, and water leaves the turbine rotor at ambient pressure.

After that, the cross-flow turbine changes the water pressure and converts it into mechanical energy. This will be led to reduce the pressure of water and increase the efficiency of the turbine and produce high torque that rotates the turbine and produce mechanical energy.

Reaction Turbine

In a reaction turbine, first, the pressure energy of water is converted into kinetic energy before supplied to the runner. So, entered water has partially pressure energy and partially kinetic energy. After that, both energies are reduced simultaneously while passing over the runner.

Hence, this turbine works on the principle of impulse reaction. The runner of this turbine is under pressure (above atmospheric pressure). Therefore, the blade of this turbine is filled with water in all conditions.

Examples of reaction turbines are Francis, Kaplan, and Propeller turbines.

Francis Turbine

Francis turbine is the most popular turbine compared to all other types of turbine used in the hydroelectric power plant as it has high efficiency and wide range of water head. This turbine is useful in the plant which has available water head between 130 to 2000 feet.

A Francis turbine can work on both orientations; vertical as well as horizontal. The rapid water strikes the turbine and flows towards the center of the turbine. It leaves the turbine axially parallel to the rotation axis once the water has flown through the turbine.

Propeller Turbine

The propeller turbines are used in low-head plants. This type of turbine has a fixed or adjustable propeller. The diameter of the propeller is large which results in slow rotational speed.

A propeller turbine looks like a large propeller of ships and submarines. The turbine has adjustable guide vanes. The water flow of the turbine is controlled by the vanes. To transfer the energy of water, the vanes move the water into a runner.

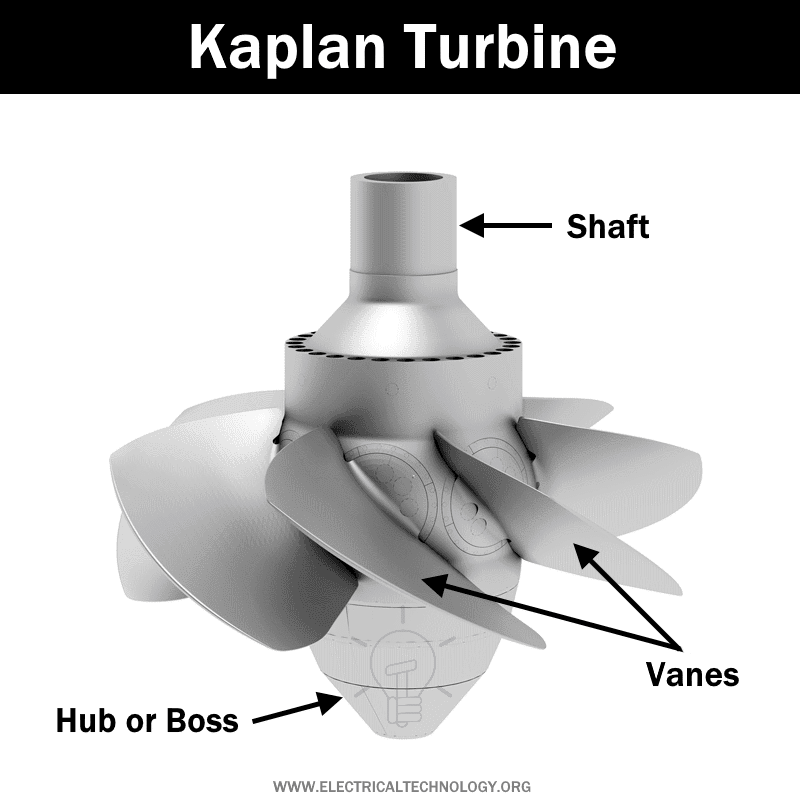

The Kaplan turbine is also a type of propeller turbine. There are many other types of turbine-like; bulb turbine, tube turbine, straflo turbine, etc. But out of these turbines, the Kaplan turbine is widely used in hydroelectric power plants.

Kaplan Turbine

Kaplan turbine is a propeller-type turbine. It has adjustable blades. It was introduced by Australian professor Viktor Kaplan in 1913. The Kaplan turbine is an evolution version of the Francis turbine.

A Kaplan turbine can work with low-head power plants. This is not possible in the case of the Francis turbine. The Kaplan turbine works efficiently with the water head ranges between 33 to 230 feet and the output of the plant between 5 to 200 MW.

The runner diameter lies between 2 to 11 meters. The Kaplan turbines are widely used in high-head and low-head hydroelectric plants.

Advantages and Disadvantages of Hydropower Plant

Advantages:

The advantages of hydropower plants are listed below.

- It is an environmentally friendly power plant and a non-polluting clean source of electrical energy.

- The operating cost of this plant is very less compared to other power plants like steam and nuclear power plant.

- It takes a very short time to start and stop the plant.

- The life of this plant is very high. The approximate life of a hydropower plant is more than 50 years.

- This plant can be operating as a base load plant as well as a peak load plant.

- Only water is required to operate this plant. So, we can say no fuel is used to run this plant and this will reduce the operating cost of a plant.

- The water released from the plant can be used for irrigation and flood control purposes.

- Compared to a steam power plant, less staff is required in a hydroelectric power plant.

- The plant is not using any fossil fuels. So, there are no byproducts like ash.

- These plants are more reliable and it has high efficiency over a wide range of load compared to other power plants.

Disadvantages:

The disadvantages of hydroelectric power plants are as listed below.

- The power developed from the hydroelectric plant depends on the quantity of water and water head. To create a water head, a dam is needed, and to store water, a reservoir is needed. So, the capital cost to build a dam and reservoir is very high.

- These plants are located in hilly areas. And in most cases, these areas are far from the load center. So, we need to transmit power via the transmission line. Which creates more transmission loss and increases the capital cost to connect the load center and powerhouse via a transmission line.

- It takes more time required to build a dam and reservoir.

- In most places, the water is available in some seasons only. And this plant is depending on the availability of water. This plant cannot operate in the dry season. So, the hydroelectric plant depends on natural rainfall.

Related Posts:

- What is Electricity? Types, Sources & Generation of Electricity

- What is Electrical Power? Types of Electric Power and their Units

- Energy and Power Consumption Calculator – kWh Calculator

- FACTS – Flexible AC Transmission System – Types of FACTS Controllers & Devices

- Why Electric Power Transmission is Multiple of 11 i.e. 11kV, 22kV, 66kV etc?

- Corona Effect & Discharge in Transmission Lines & Power System

- Why Power Transmission Cables & Lines are Loose on Electric Poles & Transmission Towers?

- Difference between AC and DC Transmission System & Power Lines

- Design and Installation of EHV/EHV and EHV/HV Substations

I am interested in learning and following new things in this field.

greetings