Types of Thermocouples and Color Codes with Advantages, Disadvantages and Applications

Temperature plays a vital role in the performance of electrical and electronic components and devices. It needs to be maintained in a specific range. However, the temperature needs to be sensed and measured first. Different types of measurement tools and instruments are used for it. One such device is a thermocouple that is used to measure the temperature.

What is a Thermocouple?

Thermocouple is a transducer that is used to measure the temperature. It converts temperature into an electrical current or voltage that is proportional to the temperature.

It is made from two dissimilar metals having different thermoelectric properties are joined together at one end while the other end remains apart. The temperature at the joined end creates thermoelectric potential at the other end that can be read using any normal multimeter. The reading is proportional to the temperature.

Thermocouple is an active sensor that does not require any power source to operate. It generates a very low voltage of about 5 μVolts/°C. It can measure temperatures up to 1200°C. It is extensively used for temperature measurement in industries.

Related Posts:

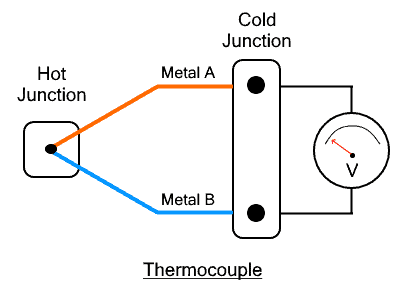

Construction

It has a very simple construction as given in the figure down below.

Thermocouple is made from two different metals having different thermoelectric properties. They are joined together at one of their ends. While the other two ends of the metals are separated. The joined end or junction is called a hot junction while the separated ends is called cold or reference junction. The metals are joined together by welding, twisting, or screwing together.

The diameter of the metal used determines the temperature range and the response time of the thermocouple. High temperature measurement requires larger diameter metals which it reduces the response time. Therefore both these factors are kept in mind while designing a thermocouple.

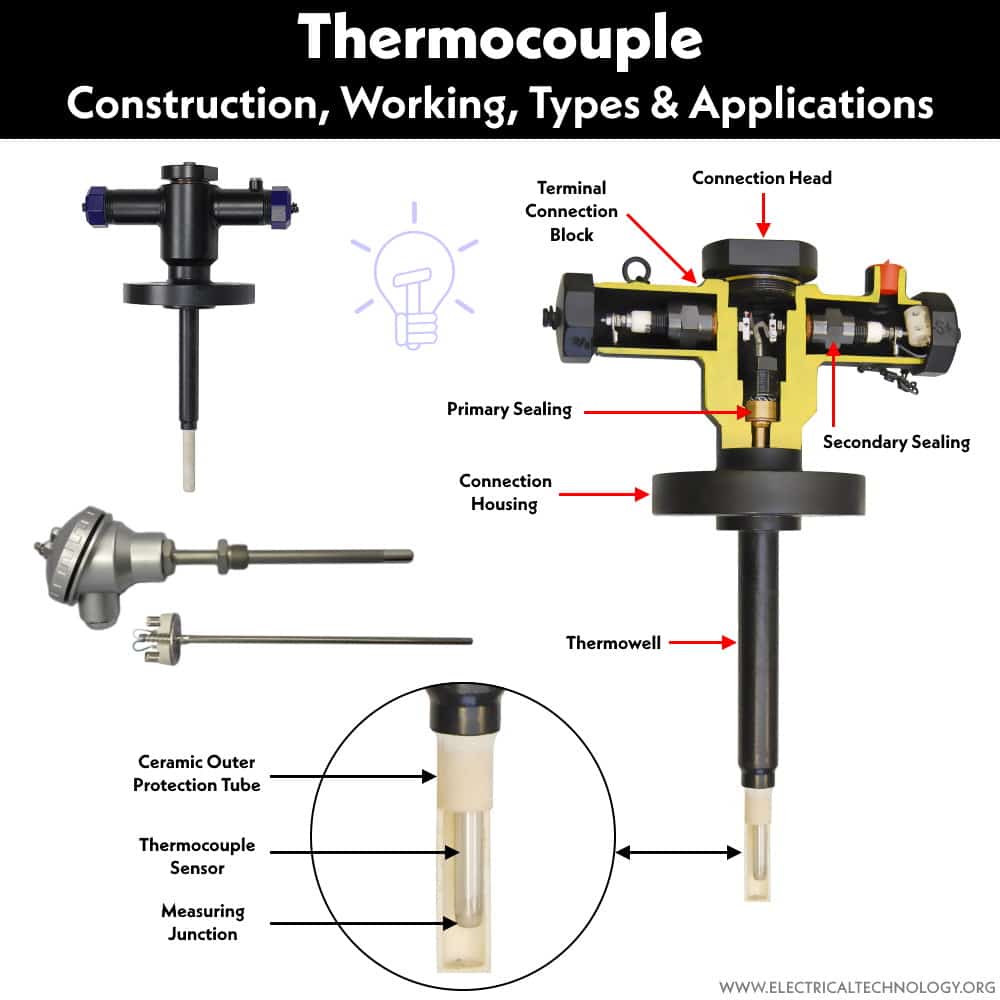

The junction at which the metals are joined together called the hot junction is used to measure the temperature. It is covered in a protective metal sheath. However, It is designed in one of the following three ways & each type has its own advantages.

Click Image to enlarge

Ungrounded Junction

In such a design, the metals at the junction are completely isolated from the protective metal sheath as shown in the figure below.

As the hot junction is insulated, the response time of the ungrounded junction thermocouple is less than grounded. However, it is more durable and due to its protective sheath, it is widely used in high pressure applications. It also reduces the effects of stray magnetic field.

Grounded Junction

In grounded junction design, the hot junction is connected with the protective metal sheath. This provides a very faster response time for high temperature ranges. But it is not suitable for an electrically conductive environment. It also reduces the noise.

Exposed Junction

In such design, the junction is exposed as there is no protective sheath over it as shown in the figure. It has the quickest response time of all designs. But they are not suitable for corrosive environments and high temperature. It is used in gas temperature measurement.

Materials used for Thermocouple

Thermocouple is made from a combination of several different types of metals but there are a few metals that offer the best performance. The pair of metals usually selected are based on the thermoelectric difference between them. Higher the difference, the higher the performance of the material.

Here is a table of some of the most often used pairs of metals for thermocouple.

| Metal A | Metal B | Temperature Range | Sensitivity μVolt/°C | Thermocouple Type |

| Copper | Constantan | -250°C – 400°C | 43 | T |

| Iron | Constantan | -200°C – 850°C | 50 | J |

| Chromel | Alumel | -200°C – 1100°C | 39 | K |

| Chromel | Constantan | -200°C – 1000°C | 68 | E |

| Platinum & Rhodium | Platinum | -50°C – 1500°C | 1-6 | S |

| Tungsten | Molybdenum | 0°C – 2700°C | 19 | |

| Tungsten | Rhenium | 0°C – 2600°C | 19 |

Based on various other characteristics these thermocouples are used for specific environments. The given table shows the chromel-constantan thermocouple to be the best for high-temperature measurements up to 1000°C with very high sensitivity. They are used in industries whereas the tungsten-rhenium thermocouples are used for very high-temperature applications.

Working Principle of Thermocouple

The working principle of thermocouples is based on the following three effects.

Seebeck Effect

Seebeck was a physicist who discovered that when two different metals or conductors are joined together at two junctions. The temperature difference between the junctions will produce emf in it. If the pair of metals is connected to a circuit it will produce a direct current in the circuit.

Peltier Effect

Pelteir effect is the opposite of the Seebeck effect. A temperature difference is generated between two different metals joined together, if a potential difference is applied across it. One of the junctions gets cool while the other gets hot.

Thompson Effect

According to the Thompson effect, a voltage difference between two metals exists along the conductor due to the temperature gradient along the two joined dissimilar metals.

Thermocouple works on the mentioned effects however; Seebeck & Peltier are the most prominent effects responsible for its operation.

As far as its operation is concerned, it is described in detail down below.

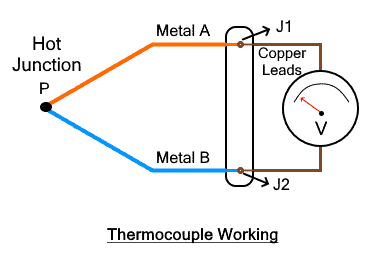

When two dissimilar metals are joined together at a junction, a small voltage called thermo-junction voltage is produced. The given figure shows two different metals A & B combined at junction P. A voltmeter is attached at the open ends of the metals A & B.

The temperature change at junction P generates a voltage difference which is measured using the voltmeter. However, the probes or leads of the voltmeter are made of copper, a different metal than the ones used in thermocouple, it results in two more junctions J1 & J2. Due to these extra junctions, an error is added to the voltage measurement.

To eliminate this error, another junction Q is added to the design as shown in the figure. This junction is also made between metals A & B. However, the two junctions J1 & J2 still exist but they both exist between similar metal A which eliminates each other’s voltage difference at the voltmeter.

Junction P is known as hot or sensing junction while junction Q is known as cold or reference junction. Reference junction temperature is known as it is kept at zero °C temp in a cold bath. Therefore, a more accurate output voltage Vo is generated based on the temperature difference between junction P & Q.

For example, if the reference temperature Tr and the sensing temperature Ts both are at 0 °C, the output voltage will be zero. If the Ts is other than 0°C, there will be emf generated proportional to the temp difference.

The output voltage of a thermocouple is very small usually a few microvolts depending on the pair of metals being used. The output voltage can be measured with various devices discussed down below.

Thermocouple Output Measurement

The output of the thermocouple is in the form of a very small emf or voltage. It needs to be accurately measured to deduce the temperature. The voltage can be measured using various devices

Multimeter

A simple multimeter can be used to measure the voltage generated by a thermocouple. Both digital, as well as analoge multimeter that has high sensitivity, can measure the voltage. The voltage reflects the temperature difference between the two junctions.

Potentiometer

A potentiometer is used to accurately measure voltage by comparing it with a known voltage. It can be either manual or automatic voltage balancing potentiometer. It is connected to the sensing or hot junction P and reference junction q whose temperature is maintained at 0 °C in an ice bath.

Amplifier

Since the output of the thermocouple is very small, it can be amplified using an amplifier into much larger values which can be easily measured using any instrument.

Laws of Thermocouple

There are basically three laws that apply to the thermocouples. Each one of them is explained below.

Law of Additive Voltage

This law states that if there are 3 different metals A, B, & C is used to measure the same temperature difference, the sum of voltages generated between A & B and voltage generated between B & C is equal to the voltage generated between A & C. The law is clearly illustrated in the given figure.

Suppose the metal A, B & C form thermocouple A-B, B-C & A-C that measures the constant temperature difference between two baths T1 & T2. Mathematically

Vac = Vab + Vbc

Law of Intermediate Metals

The law of Intermediate metals states that inserting a third metal in series between two dissimilar metals will not affect the voltage reading as long as the two junctions formed by the third metal are at the same temperature.

This law can be illustrated in the given figure. It shows a thermocouple made of metal A & B while a third metal C is added in series with metal B. This third metal forms two junctions J1 & J2. The overall temperature of the thermocouple will not change as long as the temperature at junctions J1 & J2 are the same. As both junctions are at the same temperature, the emf generated by these junctions will also be the same. Therefore, the emf generated by junction J1 cancels out the equally opposite emf generated by junction J2.

This law is not limited to only one piece of metal. In fact, two or more than two metal pieces can be added to the design but as long as the new junctions formed are kept at the same temperature, the net voltage will ne be affected.

Practical Application

- It enables the use of soldering material to join two metals without affecting the performance of the thermocouple.

- It allows the use of another cheaper third metal as a form of extension.

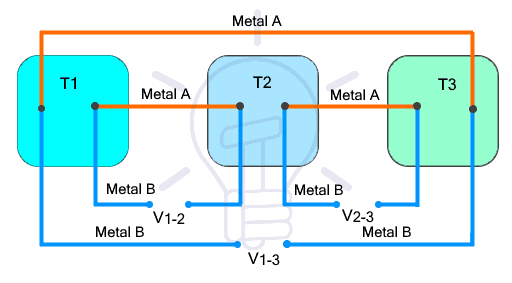

Law of Intermediate Temperature

The law of intermediate temperature states that if two identical thermocouples measure the temperature difference between T1 & T2 and the temperature difference between T2 & T3, their voltage sum is equal to the voltage generated by an identical thermocouple that measures the temperature difference between T1 & T3.

This law is illustrated by the given figure. Keep in mind that the thermocouples used are all identical. Thermocouple 1 measures the temperature difference between T1 & T2 while its output voltage is V12 while thermocouple 2 measures between T2 & T3 having an output voltage V23. The third thermocouple 3 measures the temp difference between T1 & T3 having output voltage V13. Mathematically

V13 = V12 + V23

Practical Application

- It enables us to remove any errors from the thermocouple that was previously calibrated for a different temperature at its reference junction than it is now being used.

Note: when we connect several thermocouples in series, it is called a thermopile. Thermopile has very high sensitivity and it is used for their increased sensitivity. It provides a very significant change in output voltage with a change in temperature as compared to a single thermocouple.

Types of Thermocouple

There are different types of thermocouples with color codes classified into different categories based on their performance and applications. These types are denoted by English letters as given below.

Type K

Type K thermocouple is the most common inexpensive thermocouple that has a wide range of temperature measurements. It is accurate reliable and more importantly cheap. It is also known as chromel-Alumel thermocouple.

The positive lead of type K is made of chromel. Chromel is made of 90% Nickel and 10% chromium. The negative lead is made of Alumel which is made of 95% Nickel, 2% Aluminum, 2% Magnesium and 1% Silicon.

Different color codes are used to represent and identify the positive and negative leads of a thermocouple. According to the ANSI color code, the type K thermocouple has yellow positive lead & red Negative lead. According to BS, the positive lead is brown and the negative lead is blue. According to IEC, the positive lead is green and the negative lead is white.

The temperature measurement range of type k thermocouple is from -270 °C to 1260 °C with an accuracy of ±2.2 °C. Its sensitivity is around 40 μV/˚C.

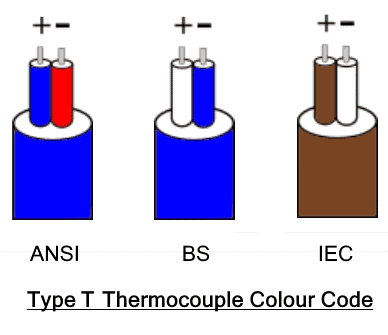

Type T

Type T thermocouple is used for low temperature measurement. It is suitable for use in an oxidizing environment.

The positive lead is made of copper. The negative lead is made of Constantan which is made of 55% Copper and 45% Nickel.

According to the ANSI color code, the color of positive lead is blue & Negative lead is Red. According to BS, the positive lead is white and the negative lead is blue. According to IEC, the positive lead is brown and the negative lead is white.

The temperature measurement range of type T thermocouple is from -270 °C to 370 °C with an accuracy of ±1.0 °C. Its sensitivity is around 43 μV/˚C.

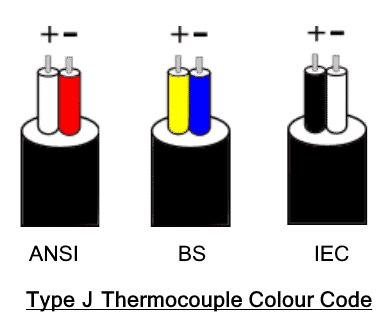

Type J

Type J thermocouple is also very commonly used. It is also suitable for use in an oxidizing environment with increased sensitivity.

The positive lead is made of Iron. The negative lead is made of Constantan which is made of 55% Copper and 45% Nickel.

According to the ANSI color code, the color of positive lead is white & Negative lead is Red. According to BS, the positive lead is yellow and the negative lead is blue. According to IEC, the positive lead is black and the negative lead is white.

The temperature measurement range of type J thermocouple is from -210 °C to 760 °C with an accuracy of ±2.2 °C. It has a high sensitivity of approximately 50 μV/˚C.

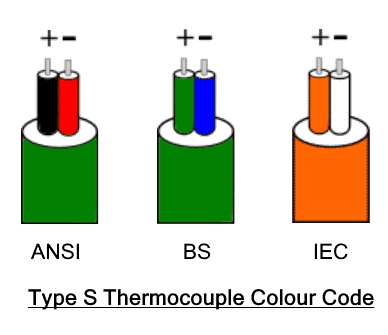

Type S

Type S thermocouple is a high-temperature thermocouple used in Biotech. However, it is also used in low temperature measurements due to its high accuracy. It is made of rare metals and that is why it is expensive.

The positive lead is made of 90% platinum & 10% rhodium. The negative lead is made of pure platinum.

According to the ANSI color code, the color of the positive lead is black & Negative lead is Red. According to BS, the positive lead is green and the negative lead is blue. According to IEC, the positive lead is orange and the negative lead is white.

The temperature measurement range of type S thermocouple is from -50 °C to 1480 °C with an accuracy of ±1.5 °C. And high accuracy at low temperature around ±1.0 °C. Its sensitivity is approximately 6 μV/˚C.

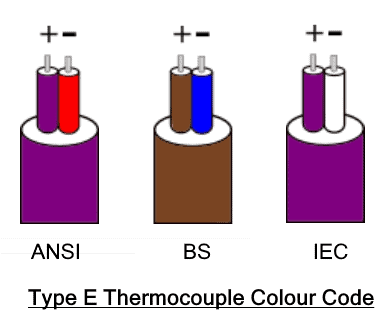

Type E

Type E thermocouple is very sensitive and provides a strong signal and high accuracy. It is used in instrumentation. It is rarely used as compared to other types. It is also nonmagnetic.

The positive lead is made of chromel. Chromel is made of 90% Nickel and 10% chromium. The negative lead is made of Constantan which is made of 55% Copper and 45% Nickel.

According to the ANSI color code, the color of the positive lead is Purple & Negative lead is Red. According to BS, the positive lead is brown and the negative lead is blue. According to IEC, the positive lead is purple and the negative lead is white.

The temperature measurement range of type E thermocouple is from -270 °C to 870 °C with an accuracy of ±1.7 °C. It has a high sensitivity of approximately 68 μV/˚C.

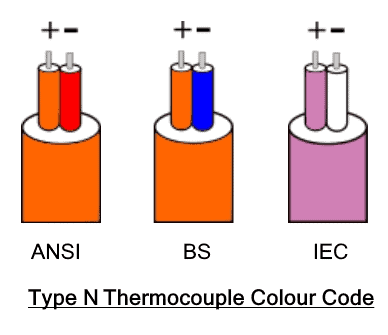

Type N

Type N thermocouple has similar performance parameters as type K with much more stability (between 300 to 500 °C)but at a higher cost.

The positive lead is made of Nicrosil. Nicrosil is made of 84.1% Nickel, 14.4% chromium, 1.4% Silicon & 0.1% magnesium. The negative lead is made of Nisil which is made of 95.6% Nickel and 4.4% Silicon.

According to the ANSI color code, the color of the positive lead is Orange & Negative lead is Red. According to BS, the positive lead is orange and the negative lead is blue. According to IEC, the positive lead is pink and the negative lead is white.

The temperature measurement range of type N thermocouple is from -270 °C to 1260 °C with an accuracy of ±2.2 °C. Its sensitivity is approximately 39 μV/˚C.

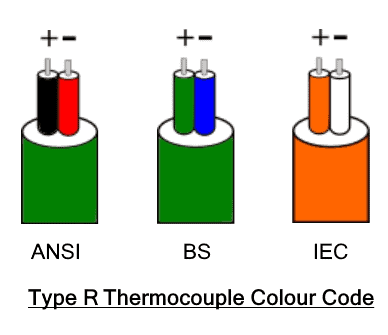

Type R

Type R thermocouple has almost similar performance as type S as it is also used for high temperatures. However, it has a higher percentage of rhodium which makes it more expensive as well as more sensitive and stable than type S. Type R is more popular in the UK while type S is popular in Europe.

The positive lead is made of 87% platinum & 13% rhodium. The negative lead is made of pure platinum.

According to the ANSI color code, the color of the positive lead is black & Negative lead is Red. According to BS, the positive lead is green and the negative lead is blue. According to IEC, the positive lead is orange and the negative lead is white.

The temperature measurement range of type R thermocouple is from -50 °C to 1480 °C with an accuracy of ±1.5 °C. And high accuracy at low temperature around ±1.0 °C. Its sensitivity is approximately 6 μV/˚C.

Type B

Type B thermocouple has the highest temperature measurement limit of all types of thermocouples. It is used for extremely high temperature measurement. It is not suitable for low temperatures due to its lower sensitivity at such temperatures. It is recommended for temperatures above 200 °C.

The positive lead is made of 70% Platinum & 30% Rhodium. The negative lead is made of 94% Platinum & 6% Rhodium.

The color code for type B thermocouple is not defined yet.

The temperature measurement range of type B thermocouples is from 0°C to 1700 °C with an accuracy of ±0.5 %.

| Thermocouple Type | Positive lead Material | Negative lead Material | Positive Lead Color | Negative Lead Color | Temperature Range | Accuracy |

| Type K | Chromel (Nickel 90% – chromium 10%) | Alumel (Nickel 95% – Aluminum 2% – Magnesium 2% – Silicon 1%) | Yellow | Red | -270 °C – 1260 °C | ±2.2 °C |

| Type T | Copper | Constantan (Nickel 45% – Copper 55%) | Blue | Red | -270 °C – 370 °C | ±1.0 °C |

| Type J | Iron | Constantan (Nickel 45% – Copper 55%) | White | Red | -210 °C – 760 °C | ±2.2 °C |

| Type S | Platinum 90% – Rhodium 10% | Platinum | Black | Red | -50 °C – 1480 °C | ±1.5 °C |

| Type E | Chromel (Nickel 90% – chromium 10%) | Constantan (Nickel 45% – Copper 55%) | Purple | Red | -270 °C – 870 °C | ±1.7 °C |

| Type N | Nicrosil ( Nickel 84.1% – chromium 14.4% – Silicon 1.4% – magnesium 0.1% ) | Nisil (Nickel 95.6% – Silicon 4.4%) | Orange | Red | -270 °C – 1260 °C | ±2.2 °C |

| Type R | Platinum 87% – Rhodium 13% | Platinum | Black | Red | -50 °C – 1480 °C | ±1.5 °C |

| Type B | Platinum 70% – Rhodium 30% | Platinum 94% – Rhodium 6% | — | — | 0 °C – 1700 °C | ±0.5 % |

Related Post:

Advantages

Here are some advantages of thermocouple

- It operates at a wide range of temperature measurements.

- It is durable and reliable and suitable for use in extreme environments.

- It has a fast response time able to measure sudden changes in temperature.

- It offers highly accurate and precise measurements

- It has a simple design & construction.

- It is an active transducer, it doesn’t require an external power source.

- It has a lower cost as compared to other temperature measurement devices.

- It is easier to measure temperature at any desired point.

Disadvantages

Here are some disadvantages of thermocouples.

- It is non-linear in nature i.e. the output voltage varies non-linearly with change in temperature.

- Its output voltage is extremely low in microvolts per °C.

- It requires amplifiers to magnify the low output voltage.

- It has lower sensitivity than most temperature measurement devices.

- It requires a reference temperature.

- Its recalibration is very difficult.

- It has lower stability.

- Noise such as radiofrequency and EMI (Electromagnetic Interference) can inflict errors in the measurement.

Applications

Thermocouples have a wide range of applications from domestic appliances to industrial plants, food industries and power generation stations. Here are some of the applications of thermocouples.

- They are used in electric arc furnaces to measure the temperatures in iron and steel industries.

- It is used in homes and offices as a temperature sensor in thermostats. It measures the temperature and regulates it using necessary actions.

- It is also used in cryogenic or low temperature applications in food industries.

- It is used in petroleum refineries & chemical plants to monitor the temperature.

- It is used to detect the pilot flame in a furnace, water heater and gas fireplace.

- It is used in various metal industries to monitor their temperature.

- It is also used to know the temperature of gases and liquids.

- It is also used to measure the temperature during the testing of the current handling capacity of switchgear.

- A Series of thermocouples also known as thermopile is used as a radiation sensor to measure the intensity of visible or infrared light.

Related Posts:

- What is a Transducer? Types of Transducers and Applications

- LVDT: Linear Variable Differential Transformer and Inductive Sensors

- Capacitive Sensor and Transducer and Its Applications

- What is Piezoelectric Sensor? Construction, Working and Applications

- Types of Resistive Sensors and Transducer, Potentiometer and Strain Gauge

- What is a Thermistor? Types of Thermistors and Applications

Why is the Ground Wire Size Smaller than the Hot Wire?

Why is the Ground Wire Size Smaller than the Hot Wire? Ukraine to Unleash an Army of Robotic Dogs on the Battlefield

Ukraine to Unleash an Army of Robotic Dogs on the Battlefield How to Wire Wi-Fi & RF Smart Wireless Remote Control Switch?

How to Wire Wi-Fi & RF Smart Wireless Remote Control Switch? Difference Between Active Transducer and Passive Transducer

Difference Between Active Transducer and Passive Transducer How to Wire Twin Timer for Repeated ON-Delay in Cycle Mode?

How to Wire Twin Timer for Repeated ON-Delay in Cycle Mode? Wire Twin Timer in Repeat Cycle & One-Shot Mode for 120V/240V Motors?

Wire Twin Timer in Repeat Cycle & One-Shot Mode for 120V/240V Motors?