What is the Difference Between VFD (Variable Frequency Drive) and Soft Starter?

Variable frequency drive or VFD and soft starter are both two different types of motor starter. Since both of these use semiconductor components to operate, people mostly confuse them with one another. Both of them can be used to safely start & stop an induction motor. Other than that they are quite different based on various other features. Some of these features are advantageous over the other.

Related Posts:

- Difference Between Soft Starter & DOL Starter

- Difference Between Soft Starter and Star Delta Starter

Before going into the list of differences between VFD and soft starter, let’s discuss what a motor starter is.

Motor Starter

A motor starter is a device that is used to safely start and stop an induction motor. An induction motor draws a huge amount of electric current (approximately 8 time its rated current) during the startup due to its low winding resistance. This huge starting current is called inrush current which can damage the internal windings of the motor and reduces its life-time & in worst case causes burnout.

The motor starters are used to reduce the starting current so it can safely start without any damage to its windings or any other mechanical parts due to the sudden jerks. It also helps in stopping the motor once the power is turned off. They also offer protection against low voltage & overcurrent protection. That’s why we need to use a motor starter.

- Related Post: Main Difference between Contactor and Starter

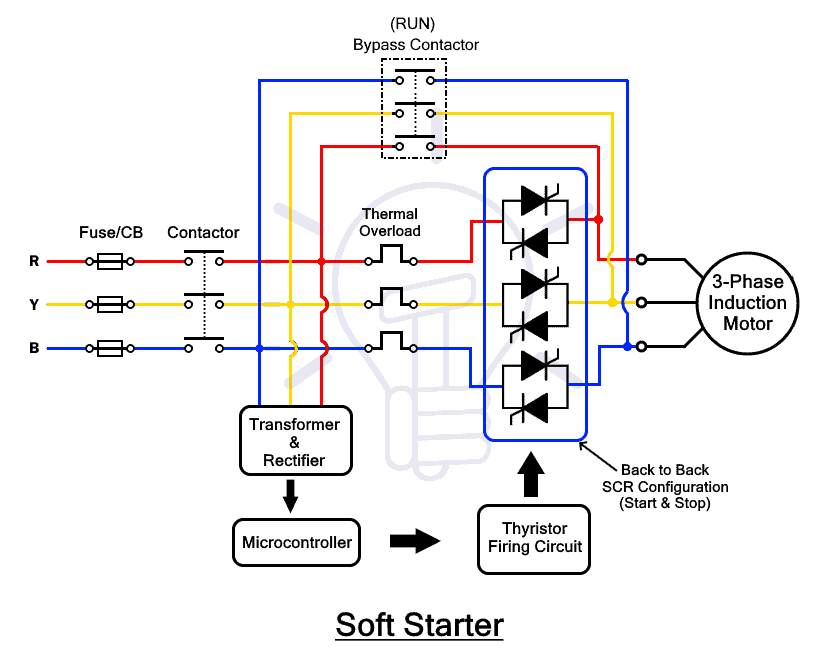

Soft Starter

It is a type of motor starter that reduces the starting current or the high inrush current by reducing the voltage applied to the motor. it uses semiconductor thyristors to control the supplied voltage. A pair of thyristors in a back-to-back formation is used to control the current flow in both directions. So, a three-phase soft starter uses 6 thyristors to offer voltage reduction on all three phases simultaneously. More info about its structure in article “soft starter”

The thyristor has 3 terminals i.e. anode, cathode & gate. The current cannot flow unless a voltage pulse is applied to the gate of the thyristor. Applying the gate signal triggers the thyristor & the current starts flowing through it. The amount of the current or voltage allowed by the thyristor is controlled by varying the angle of the gate signal called firing angle. Thus it reduces the starting inrush current supplied to the motor.

When the motor starts, the firing angle is controlled to supply low voltage which is gradually increased. The motor smoothly picks up its speed as the voltage reaches the line voltage & the motor starts running at its rated speed. Usually, a bypass contactor is used to supply line voltage directly to the motor in normal operation.

During the stopping of motor, the same operation occurs to reduces the voltage gradually to reduce the speed of the motor & eventually breaking the input voltage supply.

Since the soft starter only reduces the supply voltage during starting & stopping of the motor, it cannot vary the speed of the motor during normal operation. Therefore, they are used for constant speed application.

The soft starter does not generate any harmonics in the system. Therefore, it does not need any additional filters to remove the harmonics from the system.

It has a very compact design & its size is very smaller as compared to VFD since it requires fewer components for its operation. It also reduces the overall cost of the soft starter as compared to VFD.

Related Posts:

- DC Machine – Construction, Working, Types and Applications

- Speed Control of DC Motor – Voltage, Rheostatic & Flux Control Methods

VFD (Variable Frequency Drive)

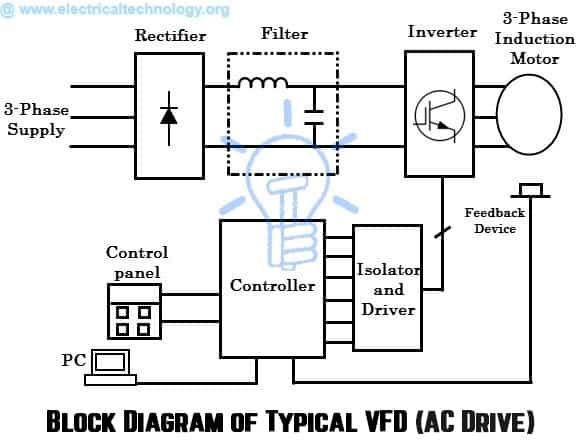

A variable frequency drive “VFD” is a semiconductor based motor starter. It can safely start & stop electric motors as well as fully control the speed of the motor during its operation. It can control the supply voltage as well as its frequency. Since the speed of the induction motor depends on the supply frequency, VFD is mostly used for varying the speed of the motor during its operation.

A VFD has three circuits i.e. Rectifier, DC Filter & Inverter. First, the AC line voltage is converted into DC using the rectifier circuit. It is then smoothen by passing through the DC filter. The steady DC voltage is then converted into AC using the inverter circuit. The inverter’s logic control circuit allows to vary the voltage as well as the frequency of the output AC voltage. It can be used to smoothly increase the speed of the motor from 0 RPM to its rated speed & sometimes above its rated speed by increasing the frequency. Therefore, it offers a complete control over the torque speed characteristics of the motor.

The VFD offer can vary the speed of the motor during its operating by varying the frequency of the supplied voltage. Therefore, it is used in applications where the speed of the motor needs to be varied. A better example would be a fan speed based on the temperature & a water pump speed based on the pressure of the incoming water.

The torque of the motor is directly proportional to the supply current & it is directly proportional to the supply voltage. We can fully control the voltage as well as the frequency to control the torque of the motor.

Traditional motor starters such as DOL starters and soft starter are cannot vary the speed of the motor. Therefore, it can either run the motor at full speed (full power) or stop the motor. While the VFD can minimize the power consumption by programming it to run the motor at a specific speed.

Unfortunately the VFD can generate harmonics in the line which is why additional filters must be connected with a VFD. Due to the use of so many circuits & components, the overall size of the VFD is larger than a soft starter. It also affects the cost of the VFD which is almost 3 times greater than soft starter.

Related Posts:

- Difference between AC Drives and DC Drives

- What is AC Drive? Working & Types of Electrical Drives & VFD

- What is DC Drive? Working and Types of DC Drives

Differences between Soft Starter & VFD

The following table shows the main differences between Soft starter and Variable Frequency Drive “VFD”.

| Soft Starter | VFD (Variable Frequency Drive) |

| A semiconductor based motor starter capable of safely starting & stopping a motor. | Semiconductor based motor starter that can safely start, stop & also vary the speed of the motor. |

| At full speed, the soft starter is bypassed using a contactor. | It operates throughout the whole operation of the motor. |

| It only regulates the AC voltage using thyristors. | It converts AC into DC & back into AC of the desired value. |

| It can only vary the supply voltage. | It can vary voltage as well as the frequency. |

| It can generate low to medium starting torque. | It can generate high starting torque. |

| There are no harmonics generated in the system. | It generates harmonics in the system. |

| It does not need any additional filters. | It needs filters due to harmonics injection in the line. |

| It is used for constant motor speed application. | It is used for variable motor speed applications |

| It is smaller in size as compared to VFD. | It is larger in size. |

| It is cheaper than VFD. | It is expensive. |

Overall, both soft starter & VFD are used for safe motor operation but the soft starter is used in application where the speed control is not necessary while the VFD is used for speed control. However, VFD should be used when high starting torque is required and high cost is not a problem.

Related Posts:

- What is Soft Starter? Its Working, Diagram and Applications

- Star Delta Starter – (Y-Δ) Starter Power, Control and Wiring Connection

- STAR-DELTA Starter Motor Starting Method Without Timer

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- What is Motor Starter? Types of Motor Starters and Motor Starting Methods

- Motor Protection – Types of Faults and Protection Devices

- Types of Electric Motors – Classification of AC, DC & Special Motors

- What is a Contactor ? Types, Working and Applications

- Why We Need to Install a Starter with a Motor?

- Single-Phase Induction Motor – Construction, Working, Types & Applications

- Three-Phase Induction Motor – Construction, Working, Types & Applications

Why is the Neutral Prong or Slot Wider on a Plug or Outlet?

Why is the Neutral Prong or Slot Wider on a Plug or Outlet? Why are there Grooved Slots in the Pins of Two Pin Plugs?

Why are there Grooved Slots in the Pins of Two Pin Plugs? How to Size a Branch Circuit Conductors with Protection?

How to Size a Branch Circuit Conductors with Protection? How to Size Feeder Conductors with Overcurrent Protection

How to Size Feeder Conductors with Overcurrent Protection How to Size Service-Entrance Conductors and Feeder Cables?

How to Size Service-Entrance Conductors and Feeder Cables? How to Size Equipment Grounding Conductor (EGC)?

How to Size Equipment Grounding Conductor (EGC)?