Types Of Cables Used In Internal Wiring and Choice Of Wiring System

Introduction

Electrical Wiring is simply a network of wires connecting various accessories for distribution of electrical energy from the supplier meter board to devices that consumes the energy such as televisions, refrigerators, fans, lamps etc.

Choice Of Wiring Systems

Before wiring a building, it is necessary one makes the right choice when it comes to the type of wiring, the size and position of fans, light points. When making choice for any wiring system for a particular installation, your choice should be based on technical and economic factors.

Generally, when making choice for a particular system of wiring, the following factors should be considered;

- Cost of wiring: The initial cost of the wiring system to be chosen or selected is one of the paramount factors to be considered. It should be economical and safe.

- Durability: When making choices for wiring system, the wiring type should be durable (long lasting) and should also be of proper specifications and in accordance with assessed life and type of building to be wired. You should not carry out cleat wiring for a permanent building because cleat wiring is suitable for temporary buildings only. Any wiring should withstand wear and tear that may result due to unfavorable weather. The cables used should be able to carry maximum current without overheating.

- Permanency: The wiring should not deteriorate by the action of weather, fumes, dampness etc. the cables should be resistant to harsh weather and chemical attacks.

- Accessibility: Facilities used in the wiring should be available (within range) and accessible when the need for alteration, extension or renewal arises.

- Appearance: The wiring should provide a good look after its installation. If cleat or casing – capping wiring is used in a modern building, it will spoil the outlook of that building. Conduit wiring is preferred mostly for modern buildings except that it’s expensive. PVC wiring system is also good for modern buildings. PVC wiring is very popular.

- Mechanical Protection: The wiring should be protected from mechanical damage during its use.

- Safety: When it comes to wiring, safety is one of the most paramount factors to be considered because electrocution is one thing you won’t have the time to give it a second thought. Where there is possibility of fire hazard, conduit wiring should be used.

- Maintenance Cost: Wiring system employed should have low maintenance cost.

- Load: The types of loads consuming the electrical energy in a building will determine the kinds of cables to be used. You cannot use a cable with small diameter for heavy loads. The cables will damage. Voltage to be employed and fire hazard and insurance standards should also be kept in mind in case of large factories.

Types Of Cables Used In Internal Wiring

The wires used for internal wiring of a building may be grouped according to

- Conductor used

- Number of cores used

- Voltage grading and

- Type of Cable insulation used.

- According to the conductor used: according to the conducting material used, cables may be divided into two classes known as copper conductor cables and aluminum conductor cables.

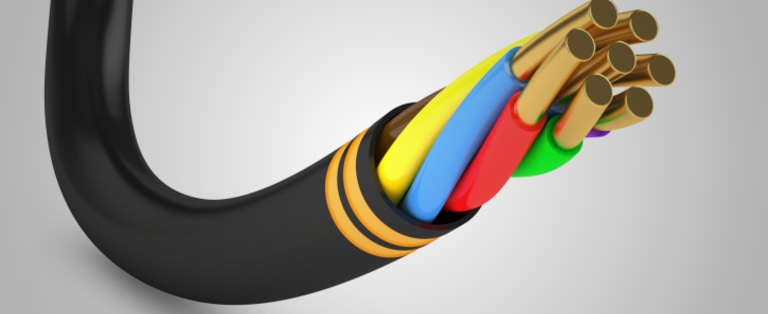

- According to the number of cores: bases on the number of cores a cable consists of, the cables may be divided into classes known as single core cables; twin core cables; three core cables.

- According to the voltage grading, the cables may be divided into (I) 250/440 volt cables and (II) 650/1,100 volt cables.

- According to the type of insulation used: these types of cables may be categorized as;

- Vulcanized Indian – Rubber (VIR) insulated cables.

- Tough rubber sheathed (TRS) or cab tyre sheathed (CTS) cables.

- Polyvinyl Chloride cables (PVC)

- Lead sheath cables

- Weather proof cables

- XLPE cables

- Flexible cords and cable

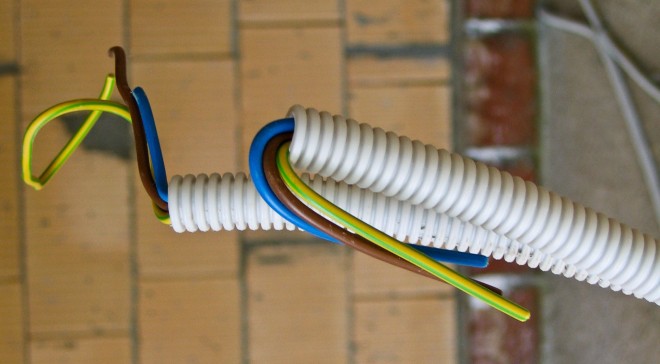

Flexible cables are cables containing one or more cores each formed of a group of wires, the diameter of cores and of the wires being very small in order to give it flexibility.

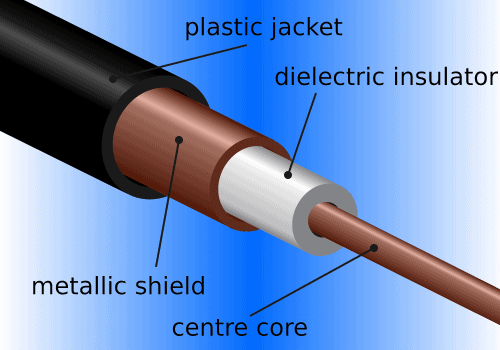

Also read : Why Coaxial Cables are Highly Insulated?

The cables are used as connecting wires for purposes as such as ceiling rose up lamp holder or from socket out – let to portable apparatus such as radios, fans and lamp holders etc. They are of different colors and thickness. The flexibility of the cable prevents it from easy breakage. XLPE and PVS cables are insulated using polymers. XLPE cables are of more advantage because they have high current rating and longer life span. They are not suitable for electrical wiring.

Also read: How To Locate Faults In Cables? Cable Faults, Types & Causes

Reasons Why PVC Cables Are Widely Used For Internal Wiring

The reasons are as follows;

- PVC insulation provides better flexibility for the cables

- PVC insulation has better insulating qualities

- PVC insulation is not affected by chemicals

- PVC insulation has thin layer which will give smaller diameter of cables which makes it possible to accommodate more wires in the conduit of a given size unlike VIR or CTS wires.

Also Read:

- Why Power Transmission Cables & Lines are Loose on Electric Poles & Transmission Towers?

- How to Find The Suitable Size of Cable & Wire for Electrical Wiring Installation

- Wire & Cable Size Calculator in AWG

- Tiny Cylinder in Power Cords & Cable. Why?

What is the Correct Wire Size for 100A Breaker and Load?

What is the Correct Wire Size for 100A Breaker and Load? What is the Right Wire Size for 90A Breaker and Load?

What is the Right Wire Size for 90A Breaker and Load? What is the Correct Wire Size for 80A Breaker and Load?

What is the Correct Wire Size for 80A Breaker and Load? What is the Suitable Wire Size for 70A Breaker and Load?

What is the Suitable Wire Size for 70A Breaker and Load? IEC and BS 7671 Requirements for Consumer Unit and Distribution Board

IEC and BS 7671 Requirements for Consumer Unit and Distribution Board National Electrical Code (NEC) Requirements for Panelboards

National Electrical Code (NEC) Requirements for Panelboards