What is a Contactor? Construction, Working, Types, and Applications

What is an Electrical Contactor?

A contactor is an electromechanical control device that used to make or break the connection between the load and power supply. The use of a contactor is similar to the relay. But the device used for higher current carrying application is known as a contactor and the device used for lower current applications is known as Relay.

A contactor has several contacts as per the application and load. Generally, these contacts are normally open (NO) contact. And hence the load is shut off when the coil of the contactor is de-energized. But the contactor can design for both normally open and normally close applications. The most common application of contactor is in the starter that used to turn ON and OFF the equipment like motor, transformer, etc.

A contactor is an electrically controlled switch used for switching a power circuit, similar to a relay except with higher current ratings. A contactor is controlled by a circuit which has a much lower power level than the switched circuit. Contactors are oftenly used for 150 Hp motor.

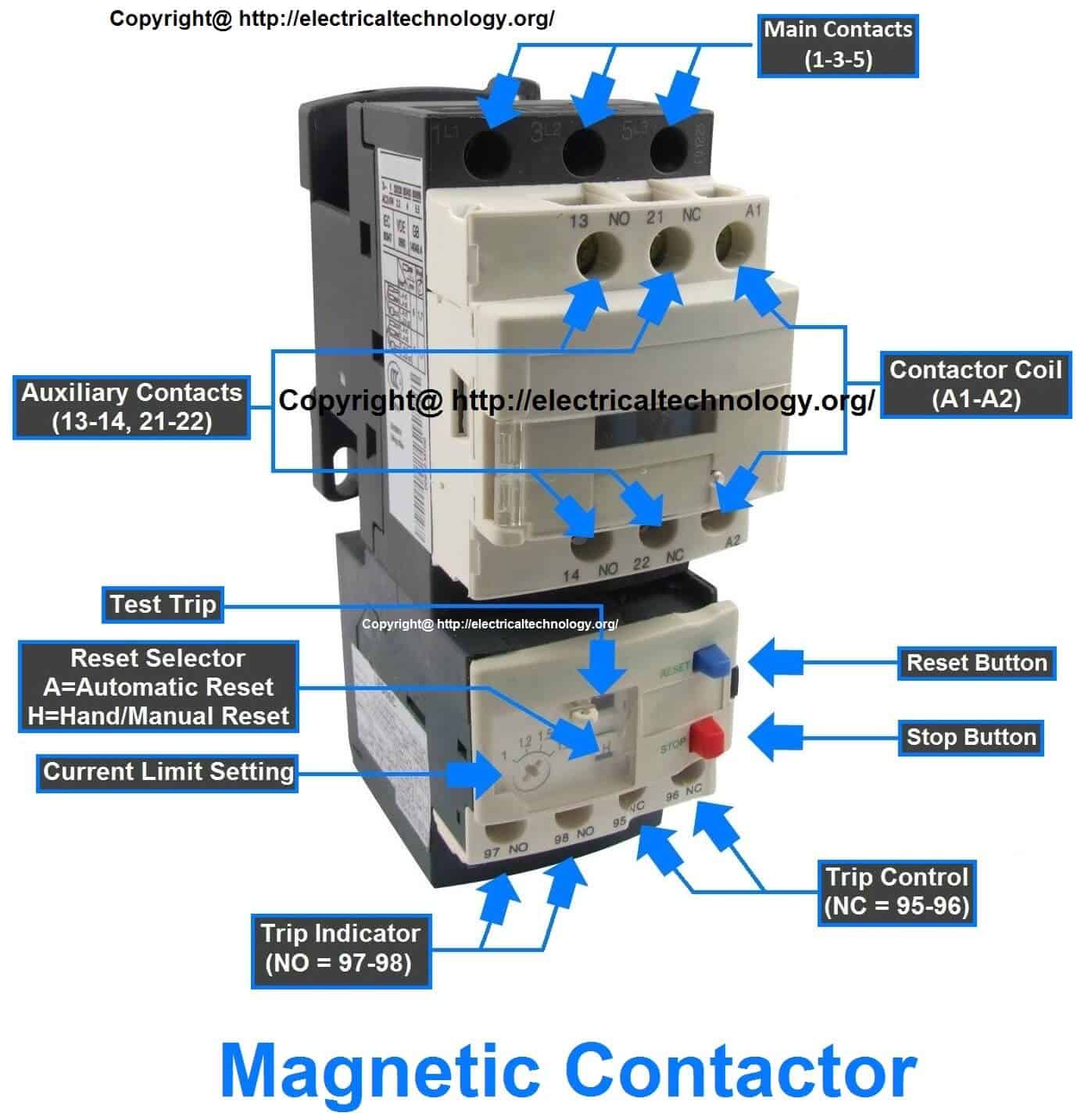

Magnetic Contactor

Magnetic contactor is a device or switch which operates magnetically and close or open the electric circuit when needed. More details are as follow.

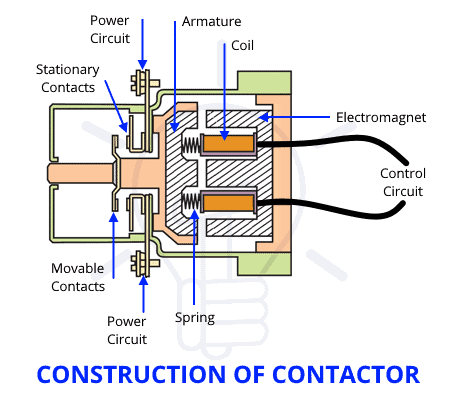

Construction of Contactor

A contactor has three main parts;

- Coil or Electromagnet

- Encloser or Frame

- Contacts

Coil or Electromagnet

The coil is wound on electromagnetic core and behaves as an electromagnet. Generally, it has two parts, one is a fixed part and the second is a movable part. A spring is connected between both parts. Hence, there is a spring return arrangement. A rod is connected with the moving part. This rode is also known as an armature. When a force of coil is more than the force of spring, both contacts are connected and when the force of spring is more than the force of the coil, both contacts are extracted with each other.

A very small amount of current will flow through the spring from the supply or external control circuit to excite the core of the electromagnet. For AC applications, the electromagnetic core is made up of laminated soft iron to reduce the eddy current. For DC applications, there is no issue of eddy current, the core is made up of solid steel.

Encloser or Frame

The encloser is used to protect the internal parts of the contactor. It is made up of plastic, nylon 6, ceramic, or Bakelite. It provides housing to the electromagnet and contacts. The encloser is used to insulate the contacts and provide protection from the dust, oil, weather, and other explosion hazards. It avoids direct touching of contact when it is powered.

Contacts

This is the only component from which the entire load current will flow. Hence, it is a very important component of the contactor. The contacts are classified as power contact, auxiliary contact, and contact spring. There are two types of power contact; stationary contact and movable contact.

The material used for the contacts has stable arc resistance and high welding resistance. These materials must withstand mechanical stress, erosion, and arc. The resistance of this material is as low as possible because the full load current will pass through the contacts. For the low current application, these contacts are made up of silver cadmium oxide and silver nickel and for high current application and DC current, it is made up of silver tin oxide.

The armature of the electromagnet is connected with the moving contact. Hence, the moving contact moves with the action of an electromagnet and connect/disconnect with the fixed contact.

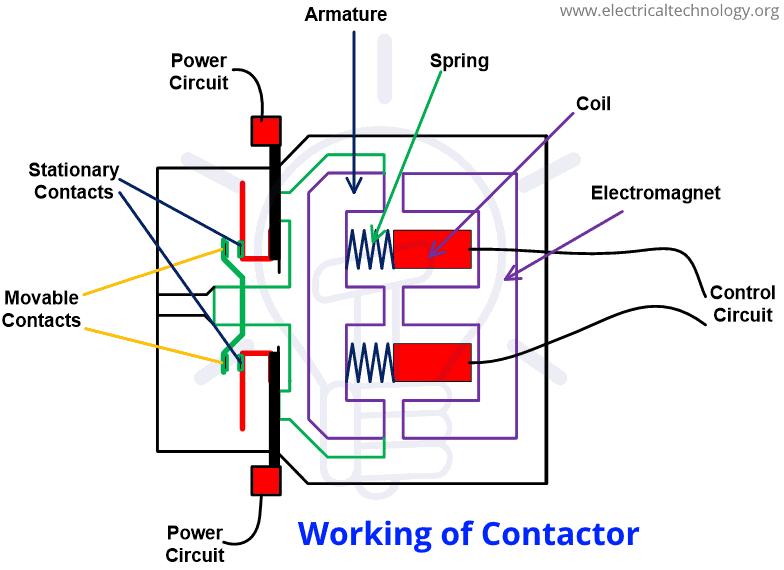

Working of Contactor

An electromagnetic field produced when the electromagnetic coil is energized. As we have seen in the construction, the moving contact of the contactor is connected with the armature (metallic rod) of an electromagnet.

When an electromagnetic field produced, the armature experiences the force and pulls towards the fixed contact. The force produced by the coil is more than the force of the spring. Both contacts remain in this position until the coil is not de-energized.

Once the coil is de-energized, the electromagnetic force is zero and the armature pulls back due to the force of spring. And return in the normal condition (OFF position). The contactors are designed for the rapid ON-OFF operation.

The input of the contactor coil may be AC or DC or in some cases, the universal coil is used as an electromagnetic coil. The universal coils operate on AC and DC both. A small amount of power loss occurs in the contacts and an economizer circuit is used to reduce this loss.

While making and breaking of contacts, an arc is produced between the contacts. This arc may reduce the life of contactor as it increases the temperature of contacts. Due to arc, harmful gases are produced like mono-oxide. Hence, there are several methods are used to control and extinction of arcs.

The contactors are selected base on load current and voltage, the control range of voltage, and application based on utilization category. If you want to check the connection of contacts are open or close, you can check it with the help of ohm-meter. Connect the ohmmeter between the input and output contacts, if the meter shows infinite reading the contacts are open and if the meter shows zero reading the contacts are closed.

Types of Contactors

Knife Blade Switch

This is the oldest type of contactor that used ON and OFF electric motors. It consists of a metal strip with a lever. The lever is used to pull-up and pull-down metal strips. This is a manual contactor. And it is very difficult to fast turn ON and OFF manually. There is also a chance to wear out the contacts.

The full load current will pass through the contacts and hence for large motor, the full load current is very high. In this condition, there is a problem of arc production between the contacts and it is difficult to quench the arc. The second problem is the power loss. As the current is very high, a large amount of power will drain by the contacts. And the third problem is safety. Therefore, this type of contactor needs improvement. The life of this contactor is very short as there is a chance of corrosion of contacts due to moisture. Due to the problems and risks of the operation, this contactor is rarely used.

Manual Contactor (Double Break Contactor)

There are lots of disadvantages to knife blade contactors. Hence, to overcome these disadvantages, a manual contactor was invented. This type of contactor is safe to operate with a smaller unit.

It allows you to work with more current in a smaller space. The double break contacts divide the connection and create two sets of contacts. As the name suggests, it cannot control by the remote or wireless, it must operate by manual control. So, the operator turn-on and off manually.

Magnetic Contactor

The design of this type of contactor is most advanced among all other types of contactors. This is an electromagnetic type contactor and it can operate automatically. It requires a small amount of control circuit to turn on and off the load. Therefore, the operation of this contactor is safe compared to manual contactor. This is the most used contactor in industrial applications. It operates electromechanically and hence; it requires a very small amount of current to make a connection between the load and power supply.

What is the difference between contactor and relay?

- The contactor is used for high voltage switching applications and the relay is used for low voltage switching applications. Generally, if the load current is more than 15A, the contactors are used and if the load current is less then 15A, the relay is used.

- The size of the contactor is large compared to the size of the relay.

- The maintenance of contactor is easy while in most of the conditions, the relay cannot repair.

- In most cases, the contactors are connected in normally open contacts and the relays are connected as normally closed contacts.

- The switching time of the contactor is slow compared to the relay.

Related Posts:

Application of Contactors

The contactor is used in the following applications.

- The most common application of contactor is in the motor starter. It is used with overload and short circuit protection for the industrial motor.

- The contactors are used for the automation of lights for industrial, commercial, and residential lighting applications. For this type of application, latch type relay is used. In this type of relay, two coils are used. One for open contact and second for close contact.

- Single pole contactors are used to operate 12VDC load in the vehicle.

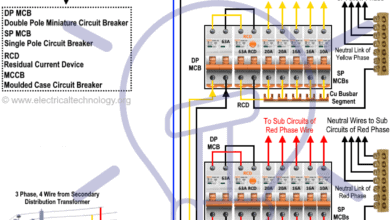

- The use of contactors with the circuit breaker assures the safety of the operation of load in industries. And in such an application, it is used to fast switching of a load.

- It is used in mercury relay and mercury-wetted relay.

- Two-pole (3-wire, 1-phase) contactors are used to operate 240VAC load like air conditioner.

Related Posts:

- What is Motor Starter? Types of Motor Starters and Motor Starting Methods

- What is Soft Starter? Its Working, Diagram and Applications

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- Factors of Contactor Contact Design

- Rated Characteristics of Electrical Contactors

- Why We Need to Install a Starter with a Motor?

- Star Delta Starter (Y-Δ) Starter Power, Control and Wiring Connection

Very helpful technical support and educative.

Good stuff

The wiring diagram of the knife blade switch is incorrect: the model shown is Single Pole Double Throw Switch, so the middle connection should receive the power supply to send it to one side or the other of the switch.

Very informative and explain in good way .

Nice blog. looking forward for more blogs about electrical equipment and its functions, thank you

THANK YOU FOR THE INFORMATION, EXACLY WHAT I WAS LOOKING FOR.