How to Start & Stop a 3-Phase Motor Using Direct-On-Line (DOL) Starter?

Power & Control Diagrams of Starting & Stopping of a 3-Phase Motor Using DOL Starter

The Direct-On-Line (DOL) starter is a widely used method for starting and stopping three-phase motors in various industrial applications. It provides a simple and cost-effective solution to control the power supply to the motor, ensuring safe and efficient operation. In this article, we will explore the working principle of a DOL starter, its components, and the step-by-step process of starting and stopping a three-phase motor using this method.

DOL Starter

A DOL (Direct-On-Line) starter is an electromechanical device that allows direct connection of a three-phase motor to the power supply. It comprises several key components, including a contactor, overload relay, and a start button. The contactor is responsible for controlling the flow of electrical current to the motor, while the overload relay protects the motor from excessive current by tripping the circuit in case of overload conditions. The start button is used to initiate the motor’s operation.

Components Required

To implement a DOL starter for starting and stopping a three-phase motor, the following components are required:

- Three-Phase Motor

- DOL Starter – (A DOL starter includes a contactor, overload relay, and start/stop buttons integrated into a single unit.)

- Contactor

- Thermal Overload Relay

- MCCB – 3P, 400V

- MCB – 2P, 230V

- 400V – Three Phase AC Supply

- 230V Single Phase AC Supply

- Wires, cables, switches and indicators: Manual control switches (such as start, stop, and reset buttons) and indicator pilot lights (for status indication).

Wiring, Power & Control Diagrams

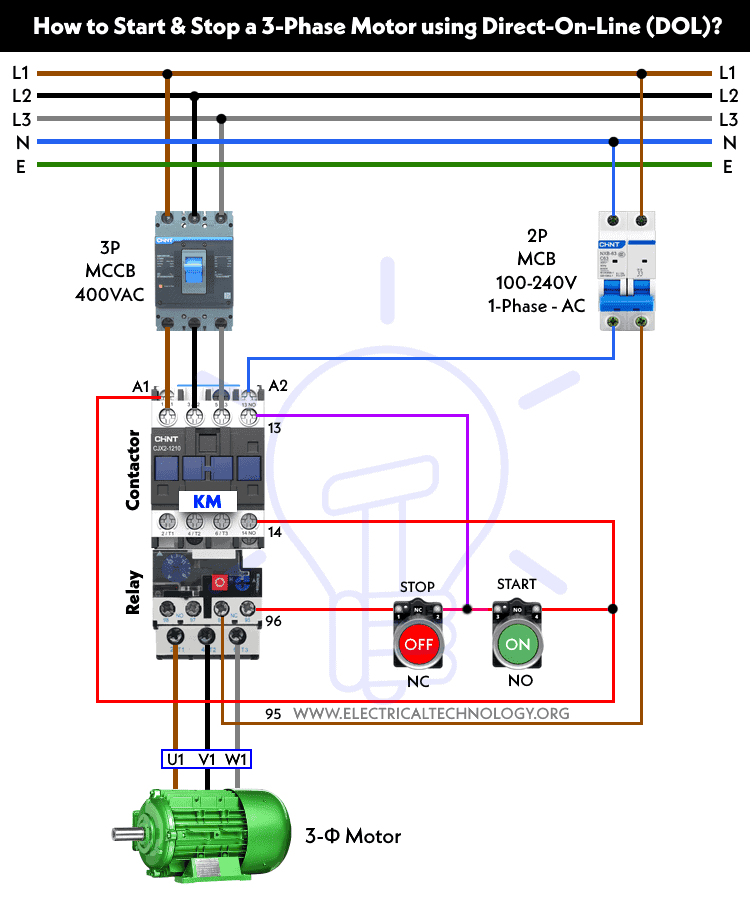

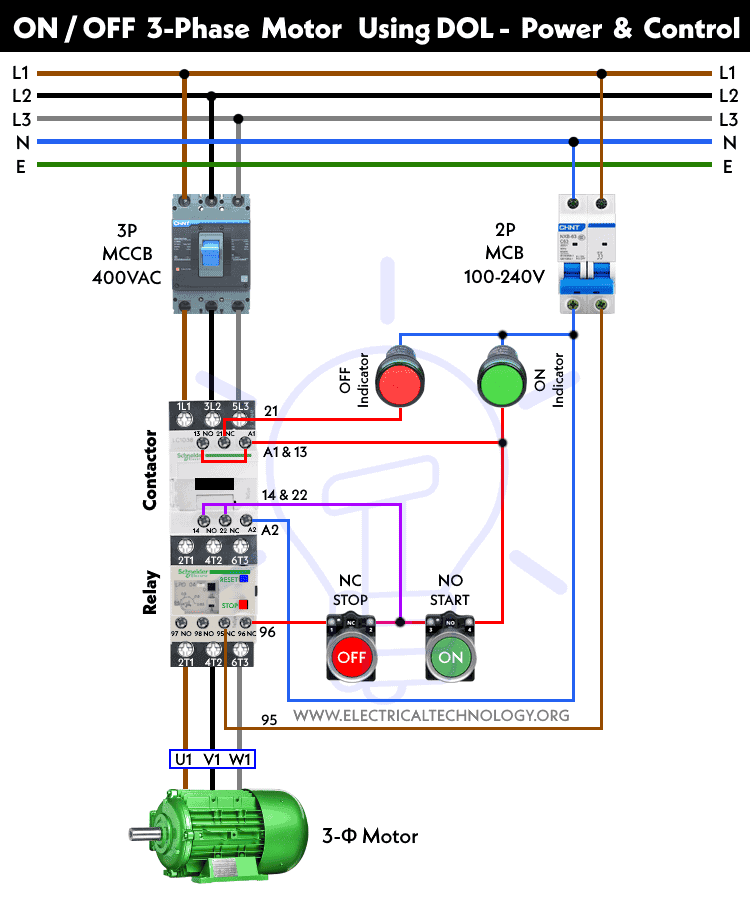

Power Diagram

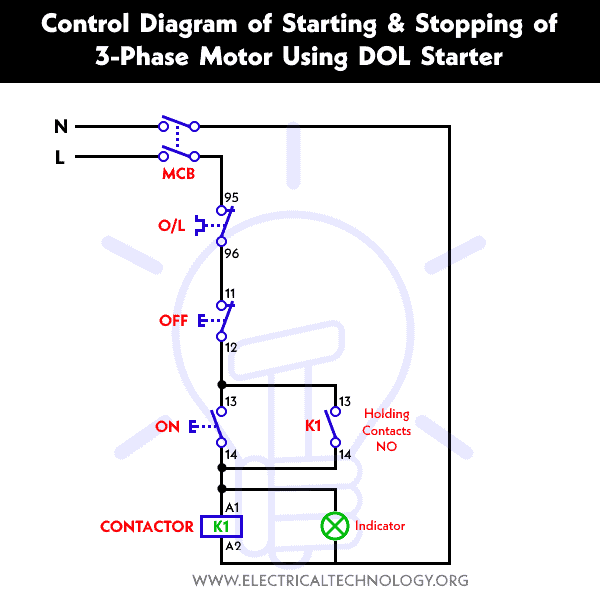

Control Diagram

Basic Wiring Diagram

Wiring Diagram with Indicators

Wiring Connections of DOL Starter

The wiring connections required to start and stop a three-phase motor using a DOL starter are as follows:

Power Supply: Connect the three-phase power supply lines (L1, L2, L3) from 400V – 3-Poles MCCB to the power terminals (1L1, 3L2, 5L3) of the DOL starter (contactor and thermal overload relay).

Motor Connection: Connect the motor’s three windings (U1, V1, W1) to the output terminals (2T1, 4T2, 6T3) of the DOL starter (from contactor and OL relay unit).

Control Circuit: Connect the control circuit of the DOL starter (contactor) to the start and stop buttons, indicator lights and the overload relay as follow.

- Connect the Neutral wire from 230V – 2-poles MCB to the A2 terminal of contactor and 1st terminals of ON indicator and OFF indicator.

- Connect a wire from 2nd terminal of ON indicator to the first terminal of ON pushbutton, A1 and 13-NO terminals of contactor.

- Connect a wire from 2nd terminal of OFF indicator to the 21 – NC terminal of contactor.

- Connect the 2nd terminal of ON pushbutton to the 1st terminal of OFF pushbutton, 14 – NO and 22 – NC terminals of contactor.

- Connect the 2nd terminal of OFF pushbutton to the 96 – NC terminal of overload relay.

- Connect a phase wire from 230V – 2-poles MCB to the 95 – NC terminal of overload relay.

Working & Operation

Once the wiring connections are correctly established, you can start and stop the three-phase motor using the DOL starter. Pressing the start button initiates the motor’s operation and Pressing the stop button interrupts the current flow and stops the motor. Here’s a step-by-step guide to the operation:

- Ensure that the power supply to the DOL starter and the motor is turned off.

- Press the start button to ensure it is in the released position.

- Turn on the power supply to the DOL starter.

- Press the start button to initiate the motor’s operation. The contactor in the DOL starter will close, allowing current to flow to the motor windings.

- The motor will start running, and it will reach its full speed based on its design and load conditions.

- To stop the motor, press the stop button. This interrupts the control circuit, de-energizing the contactor and cutting off the power supply to the motor.

- The motor will come to a complete stop, and the operation is halted.

Safety Considerations

When working with three-phase motors and electrical systems, safety should always be a top priority. Here are some important safety considerations:

- Always turn off the power supply before making any wiring connections or adjustments.

- Ensure that all electrical connections are made by a qualified electrician.

- Follow local electrical codes and regulations.

- Provide proper wire size and appropriate protection, such as fuse or circuit breaker, to prevent overcurrent and short circuits.

- Use proper personal protective equipment (PPE) when working with electrical systems.

Summary

The DOL starter provides a simple and effective method for starting and stopping three-phase motors. By understanding the components involved and making the necessary wiring connections, you can control the power supply to the motor and ensure safe and efficient operation. Always prioritize safety and consult with a qualified electrician if you have any doubts or concerns regarding the installation and operation of a DOL starter for your specific application.

Yeah, just order . I figure, they are wdeliy available so I might as well make use of them. I’m also throwing in a bunch of monolithic transistors in case I feel the need to build one instead.