Automatic Star-Delta Starter using Timer – Power, Control & Wiring Diagrams

Starting & Controlling of 3-Phase Motors Using Automatic Star-Delta Starter (Y-Δ)

A Star-Delta starter is an electromechanical device used to start and control the speed of a three-phase induction motor. This starter employs the star-delta (Y-Δ) method for starting the motor, which involves changing the motor’s winding connection from a Star configuration to a Delta configuration once the motor reaches a certain speed.

The Star-Delta starter includes a control circuit that typically consists of a timer, contactors, and overload relays. When the motor is started, it is initially connected in a Star configuration to reduce the starting current, which can be up to 6 times the motor’s full-load current. After the motor reaches a specific speed, the timer switches the winding connection to a Delta configuration to ensure the motor operates efficiently.

This starter is widely used in industries where high-power motors are required, such as in oil and gas, mining, and manufacturing. The star/delta starter offers several advantages, including reduced starting current, better control of inrush current, and reduced stress on the motor windings during starting. However, it also has some disadvantages, including increased cost and complexity, longer starting time, and reduced torque during starting.

In this tutorial, we will demonstrate the automatic star-delta (Y-Δ) starting method for 3-phase AC induction motors. This will include providing a schematic, power and control, PLC ladder, and wiring diagrams. We will also explain how the star-delta starter works and discuss its applications, as well as its advantages and disadvantages.

Working of the Automatic Star / Delta Starter using Timer

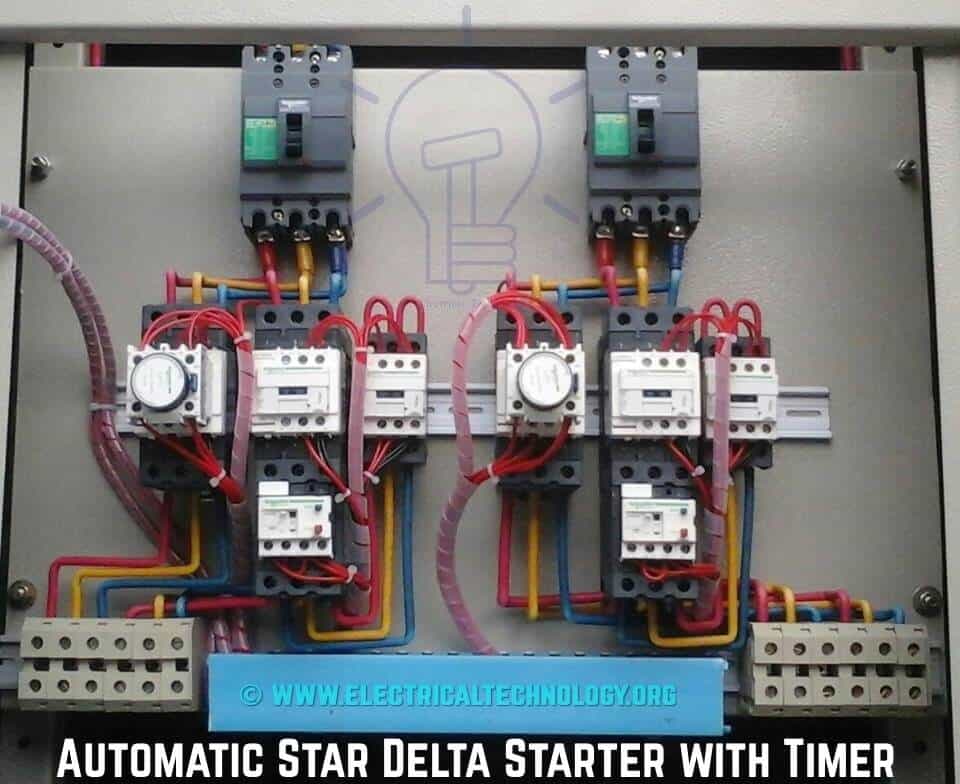

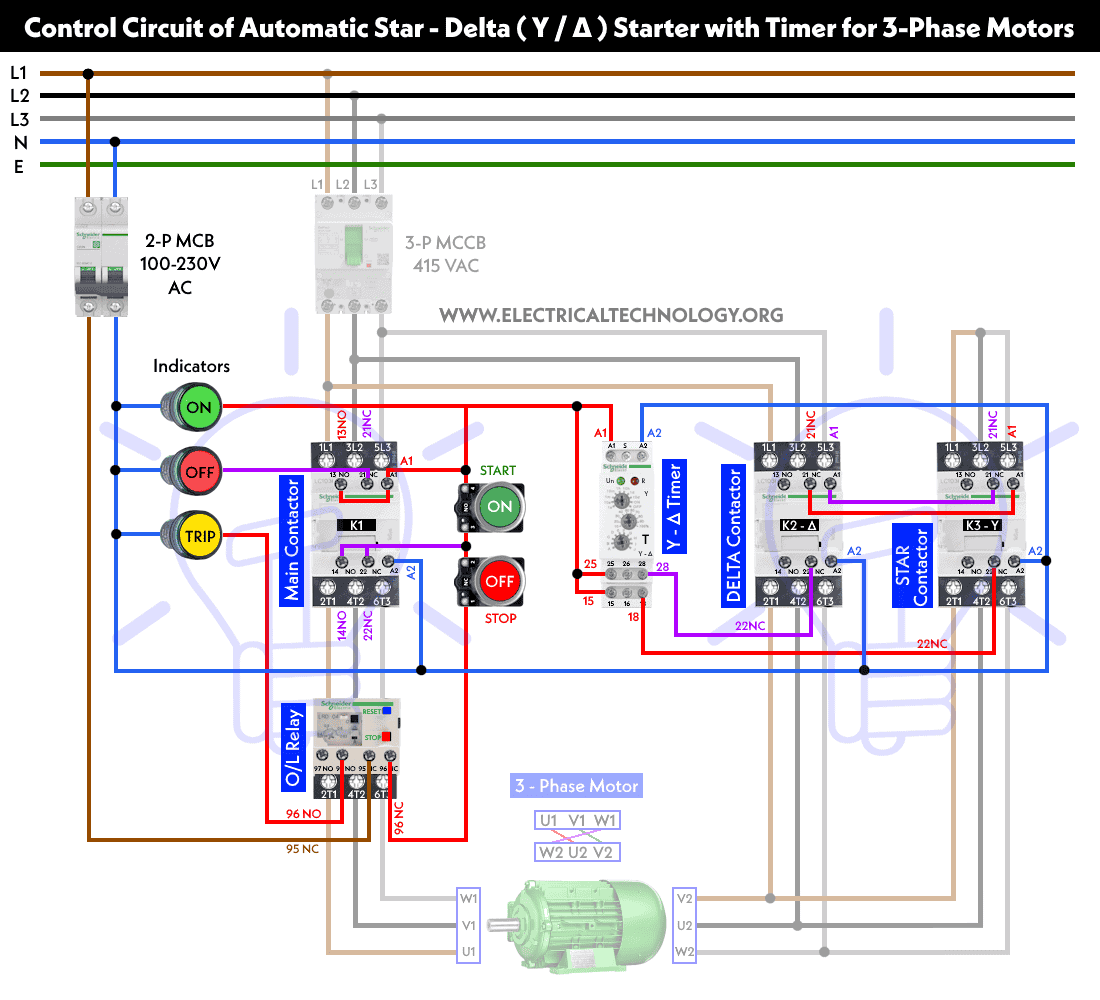

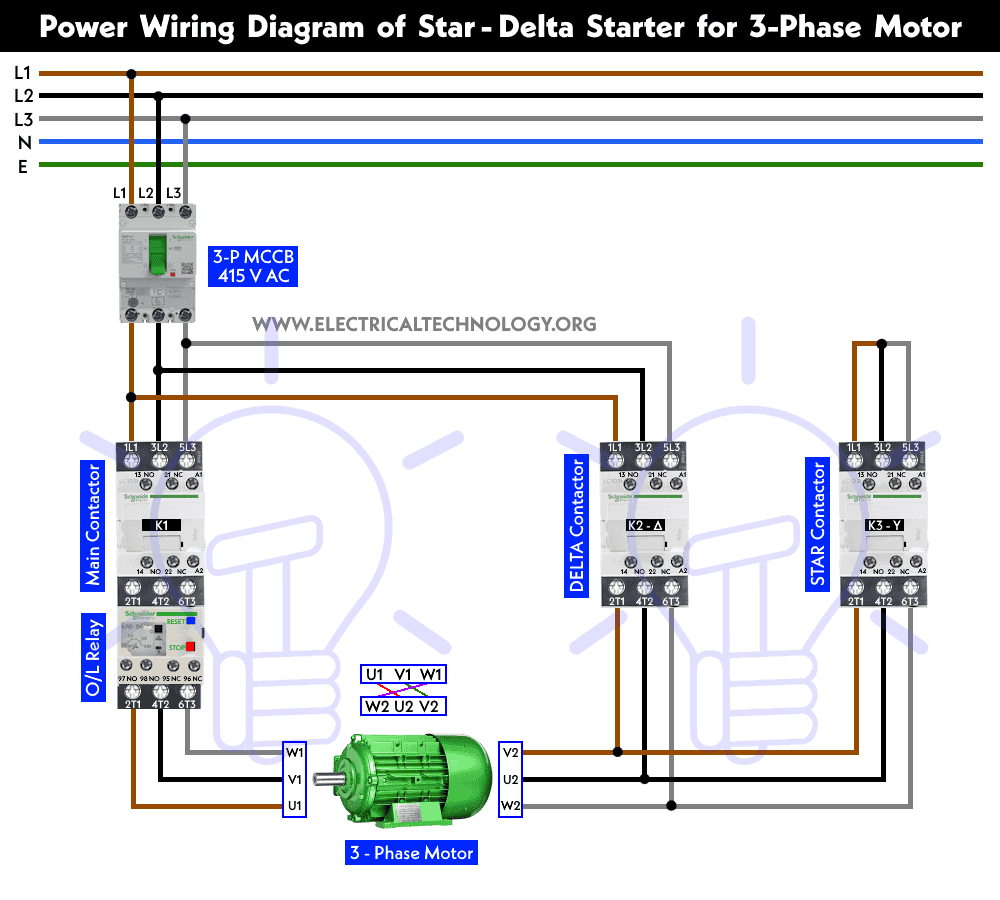

On the left-hand side, there is the main contactor with a pneumatic timer. The main contactor is always energized.

In the middle, there is the Delta contactor, which is equipped with a thermal overload for motor protection in the event that the motor exceeds the ampere rating set on the thermal overload.

On the right-hand side, there is the Star contactor, which is the first contactor to be energized with the main contactor. When the timer reaches its time limit, the Star contactor de-energizes, and the Delta contactor energizes. This allows the motor to run at full load.

Related Motor Control & Power Diagrams:

- STAR/DELTA Starter Without Timer – Power, Control & Wiring Diagrams

- Reverse/Forward Circuit for Motors using Start Delta & Timer – Power & Control Diagrams

- REV-FWD Three Phase Motor using Star/Delta Starter without Timer

Operation & Working of Automatic Y-Δ Starter

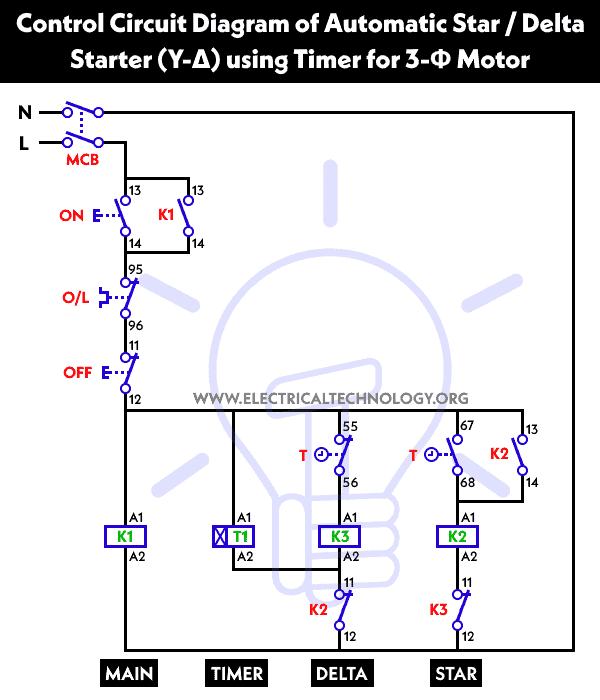

- The phase current flows from L1 to the thermal overload contact through an MCB/MCCB or general fuse, then to the OFF push button, On push button interlocking contact 2, and then to K3. The circuit is thus completed, and both contactor coil C3 and timer coil (T) are energized simultaneously. As a result, the motor winding is connected in Star, and when K3 is energized, its auxiliary open links will close, and the close links will open.

- Consequently, Contactor K1 is also energized, and the Three Phase Supply reaches the motor. Since the winding is connected in Star, each phase will receive √3 times less than the line voltage, which ensures safe motor starting. The close contact of K3 in the Delta line opens, preventing the activation of contactor 2 (K2).

- After the push button is released, Timer coil and coil 3 will receive a supply through Timer contact (Ia), Holding contact 3, and the close contact 2 of K2. When Contactor 1 (K1) is energized, the two open contacts in the line of K1 and K2 will close.

- For a specific time (generally 5-10 seconds), the motor will be connected in Star. After that, the Timer contact (T) will open (which can be adjusted by rotating the timer knob to set the time again), and as a result, Contactor 3 (K3) will turn off, and the open link of K3 (in the line of K2) will close, causing K2 to energize. When K3 is off, the star connection of the winding will also open, and K2 will close, connecting the motor winding in Delta. Contact 2 (which is in the line K3) will also open, preventing the activation of coil 3 (K3).

- Now that the motor is connected in Delta, each phase will receive full line voltage (415V), and the motor will start to run at full speed.

Related Post:

- Why Do We Need to Install a Starter with a Motor?

- Difference between Star and Delta Connections – Comparison Of Y/Δ

Wiring, Power & Control Diagrams of Star Delta Starter

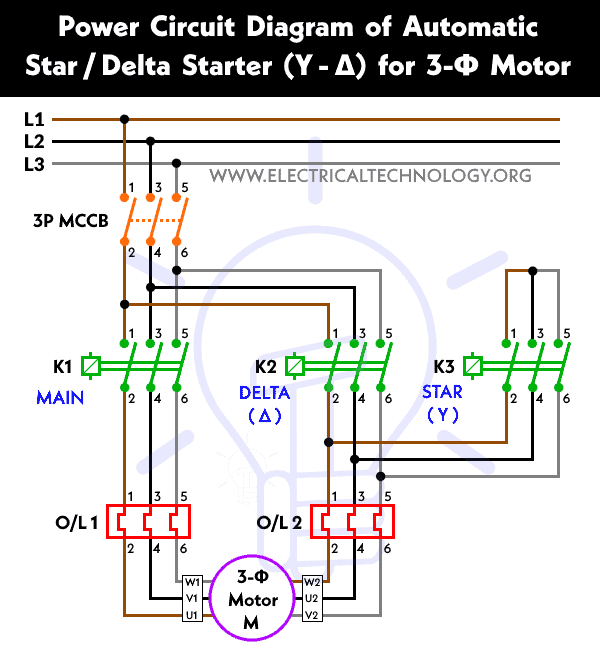

Power Diagram

Click image to enlarge

Schematic Wiring Diagram

Click image to enlarge

Control Diagram

Click image to enlarge

Control Circuit Diagram of Star Delta Starter with Timer

Click image to enlarge

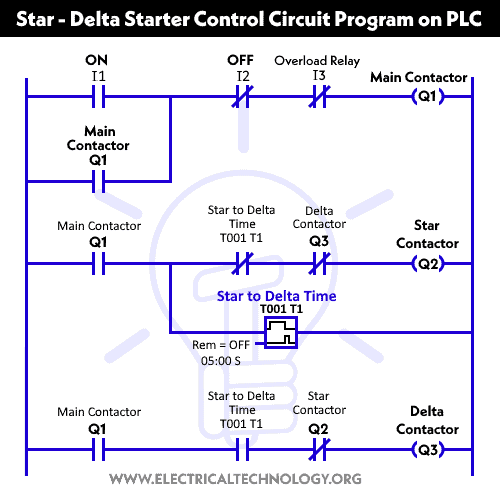

Wiring Diagram of Y-Δ Starter using PLC

Ladder Diagram of Y-Δ Starter using PLC

We have published an article that specifically covers the programming of a Star/Delta starter using a Programmable Logic Controller (PLC). The article includes detailed explanations and illustrations of the ladder, power, and control circuit diagrams for the setup.

Related Posts:

- Starting & Stopping of 3-Phase Motor from More than One Place – Power & Control Diagrams

- How to Start & Stop a 3-Phase Motor Using Direct-On-Line (DOL) Starter?

- Controlling of 3-Phase Motor from More than Two Places – Power & Control Diagrams

Legends and its Abbreviations:

- L1 , L2, L3 = Brown, Black, Blue ( 3 Phase Lines)

- CB / MCB / MCCB = General Circuit Breaker

- Main = Main Supply

- Y = Star

- Δ = Delta

- T = Timer

- K1, K2, K3 = Contactors

- O/L = Thermal Overload Relay

- NO = Normally Open

- NC = Normally Closed

- K1/NO = Contactor Holding Coil (Normally Open)

Advantages & Disadvantages

Advantages:

- Simple design and operation.

- Comparatively cheaper than other voltage controlling methods.

- The torque and current performance of the Y-Δ starter is good.

- It draws two times the starting current of the FLA (Full Load Ampere) of the connected motor.

- It reduces the starting current to approximately one-third compared to a DOL (Direct ON Line Starter).

Related Posts

- Automatic Sequential Motor Control Circuit – Power & Control Diagrams

- Reverse / Forward Circuit for 3-Phase Motors – Power & Control Diagrams

- Three Phase Slip Ring Rotor Starter – Control & Power Diagrams

Disadvantages

- Starting Torque is also reduced to one-third because the starter reduces the starting current to one-third of the rated current [as Line voltage is also reduced to 57% (1/√3)].

- It requires six leads or terminals for a Delta-connected motor.

- For Delta connection, the supply voltage must be the same as the rated motor voltage.

- At switching time (from Star to Delta), if the motor does not reach at least 90% of its rated speed, then the current peak may be equally high as in a Direct ON Line starter( D.O.L), thus causing harmful effects on the contactor’s contacts, making it unreliable.

- We should not use a star-delta starter if the required (application or load) torque is more than 50% of the three-phase induction motor’s rated torque.

Related Posts:

- Multispeed (2 Speeds, 2 Directions) 3-Phase Motor Power & Control Diagrams

- Multispeed (2 Speeds, 1 Direction) 3-Phase Motor Power & Control Diagrams

- Multispeed (3 Speeds, 1 Direction) 3-Phase Motor – Power & Control Diagrams

Characteristics & Features of Star-Delta Starter

- The starting current is 33% of the full load current for a star-delta starter.

- The peak starting torque is 33% of the full load torque.

- The peak starting current is 1.3 to 2.6 times the full load current.

- Star-Delta starters can be used only for low to high power three-phase induction motors.

- They have reduced starting current and torque.

- Six connection cables are needed for the motor terminal box.

- In a star/delta starter, there is a current peak and high transmission on mechanical load during the changeover from star to delta.

Applications

As we know, the main purpose of a star-delta starter is to start the three-phase induction motor in Star Connection and then switch to Delta Connection during operation.

It’s important to keep in mind that a Star-Delta starter can only be used for low to medium voltage and light starting torque induction motors. In the case of direct on-line (D.O.L) start, the current drawn by the motor is about 33% of its rated current, and the starting torque is reduced by about 25-30%.

As a result, the Star/Delta Starter is suitable only for light loads during motor starting. Otherwise, a heavy-load motor won’t start due to the low torque available during the acceleration phase while converting to the Delta connection

Related Tutorials and Resources used in Power & Control Wiring Diagrams for Motors

- Star – Delta Motor Control Circuit Using Delta – DVP 14SS2 Series PLC

- Star – Delta Motor Control Using Schneider Zelio Logic PLC Smart Relay

- Star – Delta Starter Motor Control Circuit Using S7-1200 PLC

- Automatic Star – Delta Starter Motor Control Circuit Using LOGO! V8 PLC

- Star – Delta Motor Control Circuit Using Omron PLC ZEN Programming Relay

- What is Motor Starter? Types of Motor Starters and Motor Starting Methods

- What is Soft Starter? Its Working, Diagram and Applications

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- What is a Contactor ? Types, Working and Applications

- Three Phase Motor Power & Control Wiring Diagrams

Its very usefully circuits .

Its very usefully circuits .

should be use one more timer for disconnect Main and Star contactor … if delta contactor faulty. its very importend.<br />

think

It's very inportant circuit for industrial aria

It's very inportant circuit for industrial aria

i also have diagram but how can i sent it to u…but may be this one helps u star connection is A1 B2 C3 close the other ends and for delta connect A1 B2 , B1 C2 , C1 A2….

Dear…Upload it to our FB page…

How this starter is built only combination of two contactors?

i want about how to calculate a resistor.<br />

What is the use of timer in this circuit and how will delta operate after a delayed timing? plz analyse ur circuit once again

Start up and Run ??

Please Describe the the control circuit diagram of Automatic Star Delta Starter with Timer for 3-phase Motor

Need ckt diagram fr three motor having star delta starter on same mcc such that only 2motor can start simultaneously not 3rd one

Motor power rating, star or delta

the timer in the circuit is used to time out c3 and time in c2 .to understand it just identify the contact of the timer in the circuit .u will see one contact is closed for c3 and one open for c2

It is a shematic diagram .I need wiring diagram of automatic star delta

You need to elaborate more, in your diagram;how the contactors are energised and fully describe how it works.

Are you sure it will work?

You might do a review about the diagram,and correct me if im wrong, it doesnt work i think.

Please elaborate in detail.. Thanks

Please help me,

I need a ATS wiring diagram by using timers and relay (three phase system)

Thanks.

I once worked on a Large Burnt out 3 Phase Motor which was used for pumping sugar from the delivery Road Tanker Lorry into a Sugar Storage Tower Silo. My boss told me the windings were unusual because they were of a STAR STAR DELTA configuration ?

Have you come across this type of motor windings arrangement before ?

Cheers

Norman Peoples

send me the star and delta control drawing with timer

Salam,

Please show with real connection.

wonderful presentation

Plz send me working principle and construction of semi automatic star delta starter….

I can’t understand reletade website information….

information of condactor&timer

Good day sir,please l will like to download some diagrams and note.

I will lik to no more about star delta diagrams, the one I will understand well

Plz send me working principle and construction of semi automatic star delta starter….

I can’t understand reletade website information….

Hi, I have this winding automatic STAR DELTA with timer and the inverter (Hz) to operate the 3 phase motor at my workplace.

Recently we have facing the motor was tripped and error shown at inverter display is “L In”, sometimes “OL”, sometimes”L U”, and “OV1” when tripped.

Could someone advice how to troubleshoot this problem?

Thanks Best Regards.

dear, please tel me how to calliberate star delta with timer.

how to calliberate star delta with timer. its urgent

I think In the actual built circuit shown as picture posted, the star contactor is connected to the thermal overload terminal from motor side, which is more safety may be, not from delta contactor side as shown in power circuit diagram.

Thanks for your valued information, it realy helped me alot.

Mohammad Khalid,

1.Current flowing through star contactor is very very less than the delta contactor.

2. Star contactor is working only for some seconds and after that Delta contactor will work continuesly.

Therefore thermal over load will never connected to star ? contactor

how can i create 555 timer circuit simulation into MATLAB.

I am intrest in electrical work succes my life

nice wasim bhai

the work is good but please how can i get the full materials on it.

thanks for your schematics

i made the start delta control circuit in fluid-sim, and i releized that it repeat the cycle when you press the start button again, and as solution i suggested to energize the main contact first.

Youssef Salimi.

I think you not put NC contact of delta contactor C2 between start push and Delta contactor coil, that’s why it repeat the sequence when you push the start again.

Please check your connection diagram you made in fluid-sim.

Thanks.

i do not understand how can coonection the star delta motor please help me

Wiring connection reference will be near the terminal box of motor or the terminal box cover. This circuit is concept of star start delta run motors. Main supply will be connected to U1, V1, W1 and the configuration of star or delta will be based on the active contactor. Timer is to delay the turning off of the star contactor and delaying the turning on of the delta contactor. But what if the voltage of start is different from the run voltage?

Please inform me have any Dealer of Automatic Star Delta Starter for 10Hp motor pump in Kolkata market? Give me address and contract no.

pls can I get any written project on a star delta control panel circuit with timer from you plssssssss

Very good article. Thank you

Please assist me on where in the circuit to connect lamps to show that it running and a siren aswell

Stanley,

Run inductor lamp you can connect parallel to the main contactor C1 or in series of any free NO(Normally Open) contact of C1 and trip inductor lamp or siren can be connected in series of NO (Normally Open) contact of Over Load protector.

Your website is very important for those engineering students go ahead.

thanks sir you have taught us and imparted us knowledge on electrical

Thanks for your information.,,

very usefull

Kindly what rates required for motors of 200 H.p for cont actors, main circuit breaker of start delta

How We can calculate for various motor power rate ?!

B.Regards

Paul

can we use H r c fuses for more safety of motor

The diagram is well presented and the Star delta is correct but the start/stop and the timer looks chaotic or not clearly illustrated

Thanks for sharing, it is a good information.

And Why 2 Overload protector relays? In second diagram.

Waste of material!!!!

Only one is enough as the current is flowing in series with both the OLs.